You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ECM Programmers ?? and Secret Squirrel Chit

- Thread starter 4x4dually

- Start date

BRE

Active member

- Joined

- May 19, 2010

- Messages

- 12,736

Ebay!

I do know that my CTS will read all of the parameters I want.It also has its own mount. LOL

I want one... Bad

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

Split it and shoot me the STL. I'll run it through the slicer and see if it will work to print.The long dimension is 12 inches. However, I can split it into two parts and build some pins into it so I can simply glue it back together.

Mucas gracias, sir.

When I get it all tweaked I'll send out a few stl files and see how much it will cost me.

Probably getting a new, rear panel, mounting one this weekend....and touch screen. :evil We'll see about that.

- Joined

- Jan 22, 2007

- Messages

- 32,085

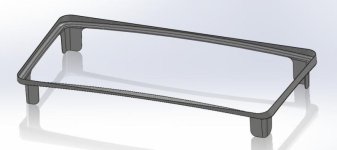

Getting closer to sending ya a file, Branodn.  It is getting real up in here....reeeeal complex. LOL Everything is a drafted extrusion, revolved cut, swept cut, loft, curve, or fillet. I think I've used almost everything in the book except "surfaces" which I don't remember a thing about.

It is getting real up in here....reeeeal complex. LOL Everything is a drafted extrusion, revolved cut, swept cut, loft, curve, or fillet. I think I've used almost everything in the book except "surfaces" which I don't remember a thing about.

Also, I know we've exchanged emails before, but I can't for the life of me find your address. PM me if-n-ya don't mind.

Also, I know we've exchanged emails before, but I can't for the life of me find your address. PM me if-n-ya don't mind.

- Joined

- Jan 22, 2007

- Messages

- 32,085

I just reduced the shell thickness to .020" and then chopped the top off it. I then ordered this much of it just to use as a test fit from Shapeways.com. It cost me $14.00 plus $6.50 shipping. So for $20 I can get the lower half of the part and see it it will actually fit in my console hole. I've done about all I can as far as test fitting 1:1 paper print outs go.

Attachments

- Joined

- Jan 22, 2007

- Messages

- 32,085

Looks like I'll just be going with turbo pressure, drive pressure, intake pressure, and exhaust temp from my XM500 module. I think reverse engineering the CAN with my funds and knowledge of it are now out of the question. Dodge and their propietary PID's and encryption can kiss my pinky toe

- Joined

- Jan 22, 2007

- Messages

- 32,085

Great info for those who like CAN.

http://intrepidcs.com/modules/CmodsDownload/upload/videos/vspy-3/08%20ReverseEngineering.wmv

http://intrepidcs.com/modules/CmodsDownload/upload/videos/vspy-3/08%20ReverseEngineering.wmv

BRE

Active member

- Joined

- May 19, 2010

- Messages

- 12,736

Edge CTS....

Dan for president!

- Joined

- Jan 22, 2007

- Messages

- 32,085

So...I've got the laptop to toggle the fog lamp enable back and forth. Yay!

It is time to get back on decipherin' the PID's from the ECM.

New idea. I'm going to drive a small relay to enable the e-brake when I start my truck. I'll have on the touch screen "auto" or "manual" mode. If I have it in "auto," it will enable on start up.

Or I could do it through the OBD port if anyone has the ability to tell me what PID it is!?!?!?!

Is there not a freakin' soul that knows out there on this forum???????????????????????????

When I figure all this out...I'm gonna be worth millions. :hehe:

It is time to get back on decipherin' the PID's from the ECM.

New idea. I'm going to drive a small relay to enable the e-brake when I start my truck. I'll have on the touch screen "auto" or "manual" mode. If I have it in "auto," it will enable on start up.

Or I could do it through the OBD port if anyone has the ability to tell me what PID it is!?!?!?!

Is there not a freakin' soul that knows out there on this forum???????????????????????????

When I figure all this out...I'm gonna be worth millions. :hehe:

Last edited:

rdix7991

Grumpy

- Joined

- Apr 13, 2009

- Messages

- 1,051

I just reduced the shell thickness to .020" and then chopped the top off it. I then ordered this much of it just to use as a test fit from Shapeways.com. It cost me $14.00 plus $6.50 shipping. So for $20 I can get the lower half of the part and see it it will actually fit in my console hole. I've done about all I can as far as test fitting 1:1 paper print outs go.

Question.

Do you just send them the file and they make you the part?

Daniel

- Joined

- Jan 22, 2007

- Messages

- 32,085

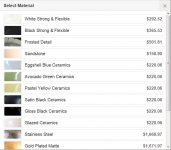

Yip. Go to Shapeways - Make Share Your Products with 3D Printing. Make a log in. Then upload your .stl file. They will review your file and make sure it is printable. Then you can go back and select what material you want and pay. It will show up at your door.

- Joined

- Jan 22, 2007

- Messages

- 32,085

rdix7991

Grumpy

- Joined

- Apr 13, 2009

- Messages

- 1,051

Yip. Go to Shapeways - Make Share Your Products with 3D Printing. Make a log in. Then upload your .stl file. They will review your file and make sure it is printable. Then you can go back and select what material you want and pay. It will show up at your door.

Ok, That is what I wanted to know. Is there an option in Solid Works to save the part as a .stl file or did you have to convert it?

Wow the Stainless is rediculous. What configuration did you upload? I'm guessing the whole display mount. I'm going to check into this.

Thanks

- Joined

- Jan 22, 2007

- Messages

- 32,085

In solidworks, just go to "save as". Select ".stl" from the pull down. Then hit "options" in the bottom right before you hit save. You can select millimeters or inches. It doesn't matter which one you choose, but remember which one it is saved in. Shapeways will ask you which unit it was created in.

Yes, that price above is for the whole thing. I had shelled it way out to make it thinner and then cut the top half off it just to test fit in the truck. It cost me $25 delivered or something like that. Full part will be around $300 when and if I can every order it.

I also just cut it in half and sent it down the hall to one of my co-workers. If his little machine can print two halves I can always glue them back together then sand and paint. $.02

Yes, that price above is for the whole thing. I had shelled it way out to make it thinner and then cut the top half off it just to test fit in the truck. It cost me $25 delivered or something like that. Full part will be around $300 when and if I can every order it.

I also just cut it in half and sent it down the hall to one of my co-workers. If his little machine can print two halves I can always glue them back together then sand and paint. $.02

Last edited: