Lostnwalmart

New member

- Joined

- Jul 19, 2006

- Messages

- 8,970

LOL

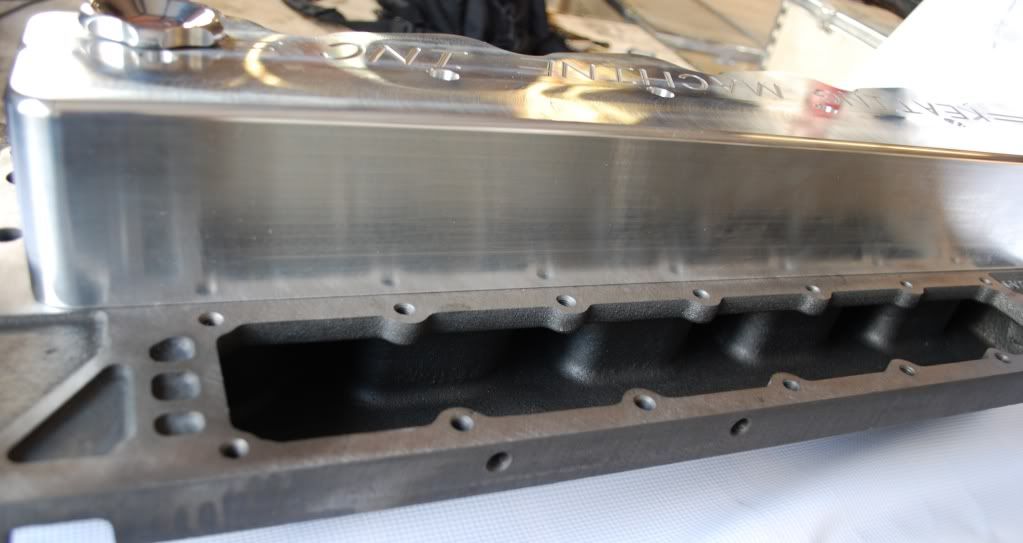

Thanks to Keating for getting this to me. A lot of people go to the SMT rocker system to keep the rocker pedestal deflection to a minimum. That is a lot of money, and with this valve cover to stabilize the rocker pedestals and some more affordable Harland Sharpe rockers you will get the performance with half the cost. Very worthwhile performance product!

This may seem like a silly question but how are you running the injection lines with this cover and a single gasket? Or will I need to go to the non single gasket cover. I may do it just to get the oil cap mine has disappeared :hehe:

Saw that but it will have to be 6 individual orings like the original piece zach was having them machine it to just have one from what I understood. i was just wondering if it would work with stock lines and one o ring, I like the idea of less.

Mike, you are going to have a beast regardless of which way you choose. The heads mojo, a piece of Sampson's hair, some of Popeye's spinach and a small piece of flux capacitor are cast into the Texas symbol. You take that off and put just a maple leaf in it's place and the thing might give it up on the first pass.

A customer put 1.970" valves in and lost a lot of flow, 20-30 CFM if I remember correctly. To gain more flow you need to do quite a lot of work with the larger valves( on the short turn)

I like the 1.850" valves as they keep the velocity up there. That will help make the bottom end a little more crisp.