You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Helix 2 vs MaxSpool? Opinions

- Thread starter dzlfarmboy

- Start date

DIESEL POWER said:cause you cant wear something that has a good oil film covering it !

Sure you can! Too high of pressures is one thing that will do it very quick! But I am sure you knew that.

Ridemywideglide

Diesel NON-Pro

- Joined

- Aug 13, 2006

- Messages

- 369

lmills said:My point is that they are saying that regrinding the cam does not affect it. That statement can be incorrect. Like I said, it may not fail, but is definitely more likely to after the material is removed. There have been plenty that have failed from regrinding the stocker. I did my research before purchasing.

I can see your point, BUT just because a cam is reground doesn't make it prone to failure.. Lack of quality check on the cam can, and that can apply to new or reground..

If I had money flowing out my ass I may not have chosen a regrind.. But I don't, so I did.. If it was a straight pull truck that I needed to turn 4500 I may not have.. It's not..

I think mine will outlast the rest of the truck..

hey, like I said. They may do fine. I am just telling you all what has been experienced first hand. The person that had it happen personally has viewed this thread. If he chooses to join in the discussion, it is up to him.

I am not taking anything away from the Maxspool. It seems to work for some of you. Like I said, I just chose to go the route of a new blank so I did not have to worry.

I am not taking anything away from the Maxspool. It seems to work for some of you. Like I said, I just chose to go the route of a new blank so I did not have to worry.

DIESEL_POWER

NGM Diesel

- Joined

- Jul 8, 2006

- Messages

- 5,178

:hehe: :hehe: thats it! i want 20 of them............but i need to know will i talk to a recording if i have a problem, or will there be a real live person to speak with..........LOL LOL :clap: :bow: :rockwoot:sootman said:Don't mind me, I'm just posting to post. I am however working on my own cam grind......it is called the "SUPERSPOOK", cause it will scare the "HELL" out of ya!!!!!!! It will be made of "unubtaininum". *bdh* I am taking orders now. :hehe: LOL If I wasn't making these cams with the help of NASA. I would run one of Greg's cams because I know he actually exists!:kick:

Tiger Rag

Glorified farm truck

- Joined

- Jul 23, 2006

- Messages

- 35

Check with the F1 dealer network and you'll receive first class customer service. Yes, I'm biased as I have a few F1 products in my truck, but I have also been well taken care of by my knowledgeable, local dealer. Don can't do it all with R&D, manufacturing, sales, and running the business. I'm sure there aren't enough hours in the day. As the president of a company you have to draw the line somewhere. Let the sales group sell, let management manage, and let manufacturing manufacture. Consider it a perk that someone on the cutting edge of research and developement comes in here to share his time with factually backed up learnings. Some of you refer to Don as arrogant, I see his views as confidence, especially when you consider how well his arguments are backed up. That's how I see it anyway.

Ridemywideglide

Diesel NON-Pro

- Joined

- Aug 13, 2006

- Messages

- 369

:hehe: :what:Tiger Rag said:Consider it a perk that someone on the cutting edge of research and developement comes in here to share his time with factually backed up learnings. Some of you refer to Don as arrogant, I see his views as confidence, especially when you consider how well his arguments are backed up. That's how I see it anyway.

I didn't see anything so far in this thread that was "factual backed up learnings".. Unless you meant the "cast nodular steel" factual learning that google disproved..

I used to deal computers and networking, so I know how much it sucks to call "tech support" only to find out they know LESS than you do..

I don't want to end up there with my truck..

Tiger Rag said:Yes, I'm biased as I have a few F1 products in my truck, but I have also been well taken care of by my knowledgeable, local dealer.

Thats why I drive south to Norfolk instead of north to Mechanicsville *cough* :hehe:

Let me take that back, Diesel Power- that was a good point about the oil analysis. So who did you call before making that post? :hehe: I know I'm new to CompD so don't pay me any mind.:what: LOL

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

If we can't get this thread back on track and leave the personal jabs out of here -this thread will be locked up.......:rules:

What suprises me is that both DonM and Greg both have decent cams for what they respectively are. . . . .

What suprises me is that both DonM and Greg both have decent cams for what they respectively are. . . . .

RascalMafia

heyyyyyyy girrrrrrrl

- Joined

- Apr 4, 2007

- Messages

- 5,514

Tiger Rag said:Check with the F1 dealer network and you'll receive first class customer service. Yes, I'm biased as I have a few F1 products in my truck, but I have also been well taken care of by my knowledgeable, local dealer. Don can't do it all with R&D, manufacturing, sales, and running the business. I'm sure there aren't enough hours in the day. As the president of a company you have to draw the line somewhere. Let the sales group sell, let management manage, and let manufacturing manufacture. Consider it a perk that someone on the cutting edge of research and developement comes in here to share his time with factually backed up learnings. Some of you refer to Don as arrogant, I see his views as confidence, especially when you consider how well his arguments are backed up. That's how I see it anyway.

so let me see if i have this right...don is busy, so very busy he cant talk to customers even when the ask him questions in direct internet public. but he can reply to this thread like 20 times a day, and still avoid the questions/concerns of already or possible customers. but there is always a response to someone that will never buy f1, and isnt even making an relevant comment.

greg, are you currently or in the future going to make a nitrous specific cam?

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

feelmecummin said:greg, are you currently or in the future going to make a nitrous specific cam?

The Max Spool version I recieved had big air, big fuel and nitrous in mind upon is design..... (24V- P-pumped with twins):evil

jkretzer

MegaCrank

- Joined

- Jul 9, 2006

- Messages

- 1,444

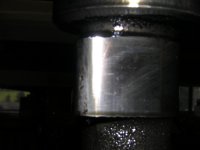

After finally catching up on reading this thread i will comment. I HAVE HAD A REGRIND FAIL!!! it was from a big name company that i will not reveal, I am tickled the way they handled it, it could not have gone smoother given the circumstances. They had no idea it was a problem but took care of everything for all the problems they had. it was first found in one of their trucks and they volunteered to call me and let me know about the situation out of their own good hearts, not many companies would have done that. i now have an extact copy of the regrind i first had, same specs. i do have pics of this cam and the flaking lobes that i will post here during my lunch but right now i need to get back to work. j

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

feelmecummin said:greg, are you currently or in the future going to make a nitrous specific cam?

give me a call , I will spec you a cam to fit your needs ,

Tiger Rag

Glorified farm truck

- Joined

- Jul 23, 2006

- Messages

- 35

Ridemywideglide said:I didn't see anything so far in this thread that was "factual backed up learnings".. Unless you meant the "cast nodular steel" factual learning that google disproved..

I agree, that one hasn't been backed up, at least not yet (that it doesn't exist). What has been backed up is that the stock Cummins cam is chilled ductile iron. The only other thing we don't know are the cam specs. I think it has been explained why that is not offered and I cannot blame him for giving away proprietary info that a lot of time and money was spent R&D'ing. It will make it more difficult for competitors to copy....at least he'll get a sale out of it as they buy one to mock.

All I really wanted to point out was that Don's dealer network are some of the most professional in the industry.

Tiger Rag

Glorified farm truck

- Joined

- Jul 23, 2006

- Messages

- 35

feelmecummin said:so let me see if i have this right...don is busy, so very busy he cant talk to customers even when the ask him questions in direct internet public. but he can reply to this thread like 20 times a day, and still avoid the questions/concerns of already or possible customers. but there is always a response to someone that will never buy f1, and isnt even making an relevant comment.

I agree to some degree of what you are saying about Don being busy but having time to post. In this business it seems that forums are a form of marketing though. If you make a post regarding your cam and how it is manufactured and have it archived for a search engine to pick up on, why not? He is reaching a lot of potential customers now and in the future with that search feature.

Regarding the Nodular Iron vs. Nodular Steel debate....

Cast Iron and Steel are very closely related, and it is the addition of a few key elements (primarily Carbon) that separate the two. Most cast irons have high level of carbons present in the molten stage (sometimes over 4%) whereas steels never have more than 2.1% and typically fall below 1%. Much like pouring sugar into tea, there becomes a "solubility limit" which means that you can only put so much "solute" into the "solvent" before it becomes "saturated". You can do things to trick the solvent into accepting more solute (raising temperature, agitatation, etc), but there is a limit. Carbon dissolved into iron in such a high quantity follows this rule, and it is the molten temperatures that allow such a high quanity to be present. When the iron is cast, however, and the temperatures cool the carbon becomes "supersaturated" in the iron and must "precipitate" out of the iron solution. In most materials, iron included, this can be a bad thing because the over saturated solute precipitates out on the grain boundries and locks them down. What this means is you get a very brittle part because the gain boundries cannot slide relative to one another. "Nodular Iron" adds certain key elements to produce "nodules" or small spheres of precipitate carbon instead of random globs or sheets throughout the grain matrix. This has the effect of producing a more uniform grain structure that is more ductile (hence the name ductlie cast iron or chilled cast iron or nodular iron). A chilled cast is often used to aid in the cooling rate of the iron to catch the iron in this nodular state before it reverts back to a less prime grain condition. It's a combination of heating and cooling rates combined with the actual material that give the product. In steels, a process called "Spheroidizing" creates a somewhat similar grain structure as nodular iron, only it is introduced through heating vs. cooling. Heat treatable aluminums also work on the idea of alloyed elements in solution and processing them in specific ways to obtain the desired result.

IMO the nodular steel vs. nodular iron becomes an issue of semantics, but it should be correctly called cast nodular iron. Steels almost always do not contain enough carbon to reach the saturation limit. Whichever you call it (steel or iron) the process is certainly the same and you end up with a decent part of this application.

Cast Iron and Steel are very closely related, and it is the addition of a few key elements (primarily Carbon) that separate the two. Most cast irons have high level of carbons present in the molten stage (sometimes over 4%) whereas steels never have more than 2.1% and typically fall below 1%. Much like pouring sugar into tea, there becomes a "solubility limit" which means that you can only put so much "solute" into the "solvent" before it becomes "saturated". You can do things to trick the solvent into accepting more solute (raising temperature, agitatation, etc), but there is a limit. Carbon dissolved into iron in such a high quantity follows this rule, and it is the molten temperatures that allow such a high quanity to be present. When the iron is cast, however, and the temperatures cool the carbon becomes "supersaturated" in the iron and must "precipitate" out of the iron solution. In most materials, iron included, this can be a bad thing because the over saturated solute precipitates out on the grain boundries and locks them down. What this means is you get a very brittle part because the gain boundries cannot slide relative to one another. "Nodular Iron" adds certain key elements to produce "nodules" or small spheres of precipitate carbon instead of random globs or sheets throughout the grain matrix. This has the effect of producing a more uniform grain structure that is more ductile (hence the name ductlie cast iron or chilled cast iron or nodular iron). A chilled cast is often used to aid in the cooling rate of the iron to catch the iron in this nodular state before it reverts back to a less prime grain condition. It's a combination of heating and cooling rates combined with the actual material that give the product. In steels, a process called "Spheroidizing" creates a somewhat similar grain structure as nodular iron, only it is introduced through heating vs. cooling. Heat treatable aluminums also work on the idea of alloyed elements in solution and processing them in specific ways to obtain the desired result.

IMO the nodular steel vs. nodular iron becomes an issue of semantics, but it should be correctly called cast nodular iron. Steels almost always do not contain enough carbon to reach the saturation limit. Whichever you call it (steel or iron) the process is certainly the same and you end up with a decent part of this application.

jkretzer

MegaCrank

- Joined

- Jul 9, 2006

- Messages

- 1,444

here are the pics of my flaking REGRIND cam that was removed with only a few thousand miles on it. the cam was awesome, spooled lightning fast and cooled really well. but as you can see there was a downside. i WILL stay away from regrinds and urge everyone else to also. They may be fine, but one will never go in my truck again. I will go with an F1 cam on my next motor that lmills and i are going to build.

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,369

Who did the regrind on that cam? Was it ever QC tested?