Teamfreeman04

Livin' the Dream

- Joined

- Jul 2, 2012

- Messages

- 424

I may have missed this already ..... I would reverify cam degree....same guy put in all the cams?

Can someone elaborate the whole loose valve lash being helpful?

just curious but are all the trucks on single turbos?

If you plan on staying under 4000 rpm there is nothing wrong with the stock cam. Put the cam money into a kick ass charger.

If you plan on staying under 4000 rpm there is nothing wrong with the stock cam. Put the cam money into a kick ass charger.

So when's that stocker going back in??

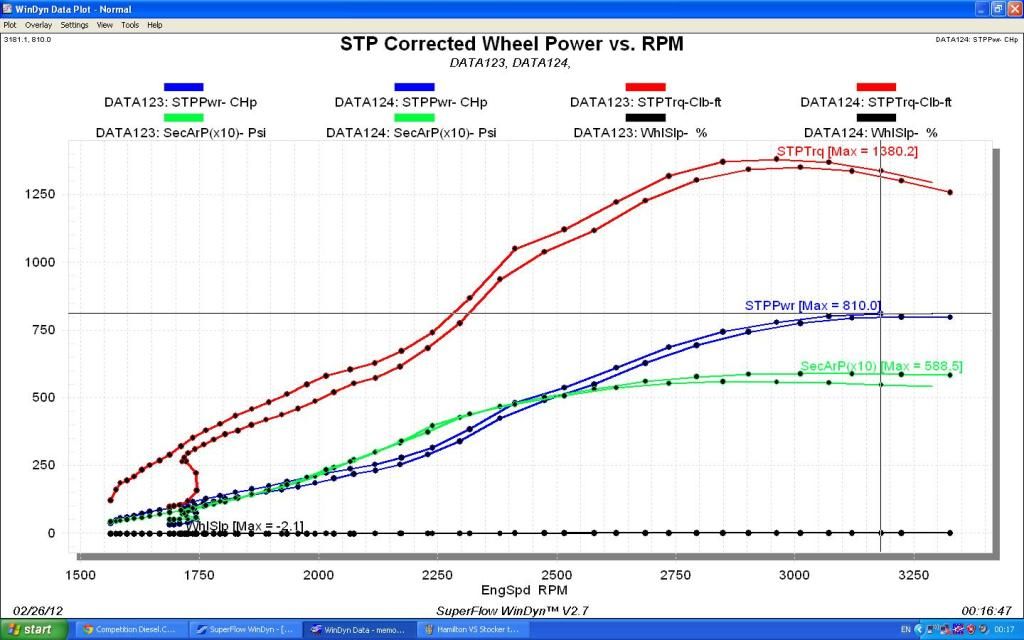

I am one of the five guys. Running a steed speed Mani, Wilson intake mani, fleece s468, 80% overs , 10.6 mm stroker, ported head, mahle ceramic coated pistons .020" over. And a 188.220. It has no balls down low. What so ever. S468 lag: http://www.youtube.com/watch?v=3VoaTm8zpFc here is a video of it.