Smokem

Turbler

- Joined

- May 10, 2006

- Messages

- 5,565

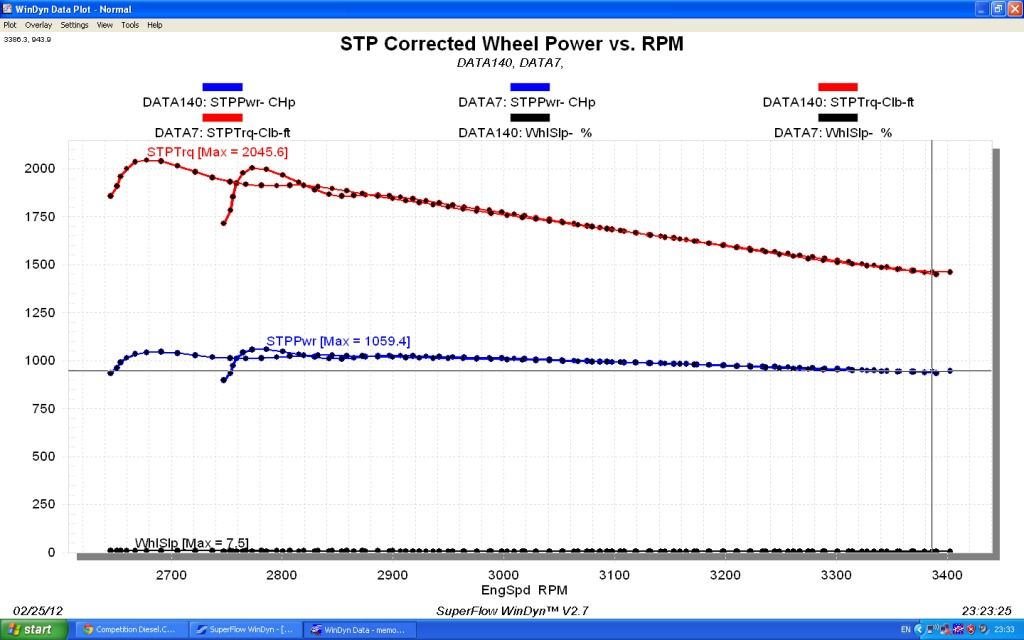

Was 1268 uncorrected at 1750us, for you 12v guys that 1750us doesn't mean anything to, there is good fuel until at least 2500us.

But it does when you put it into simple terms;

1750µs @ 2000RPM = 21° injection window

2500µs @ 2000RPM = 30° injection window

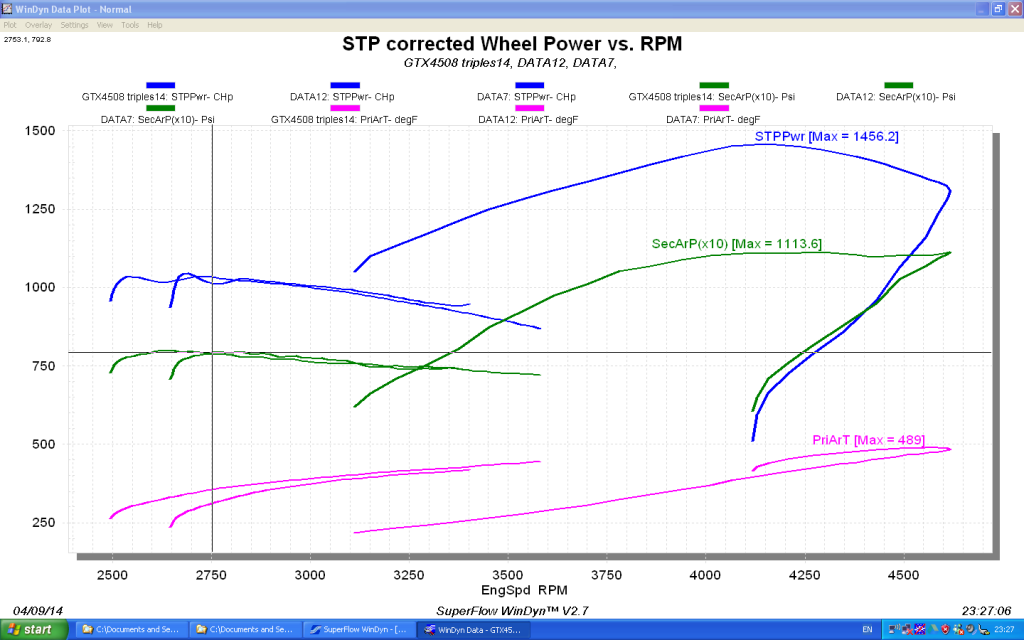

Problem is those numbers double @ 4000RPM, and this is where the CR nozzles are falling short. The big mechanical injectors are able to overcome this for one very good reason, and it has nothing to do with the holder/body.