Lostnwalmart

New member

- Joined

- Jul 19, 2006

- Messages

- 8,970

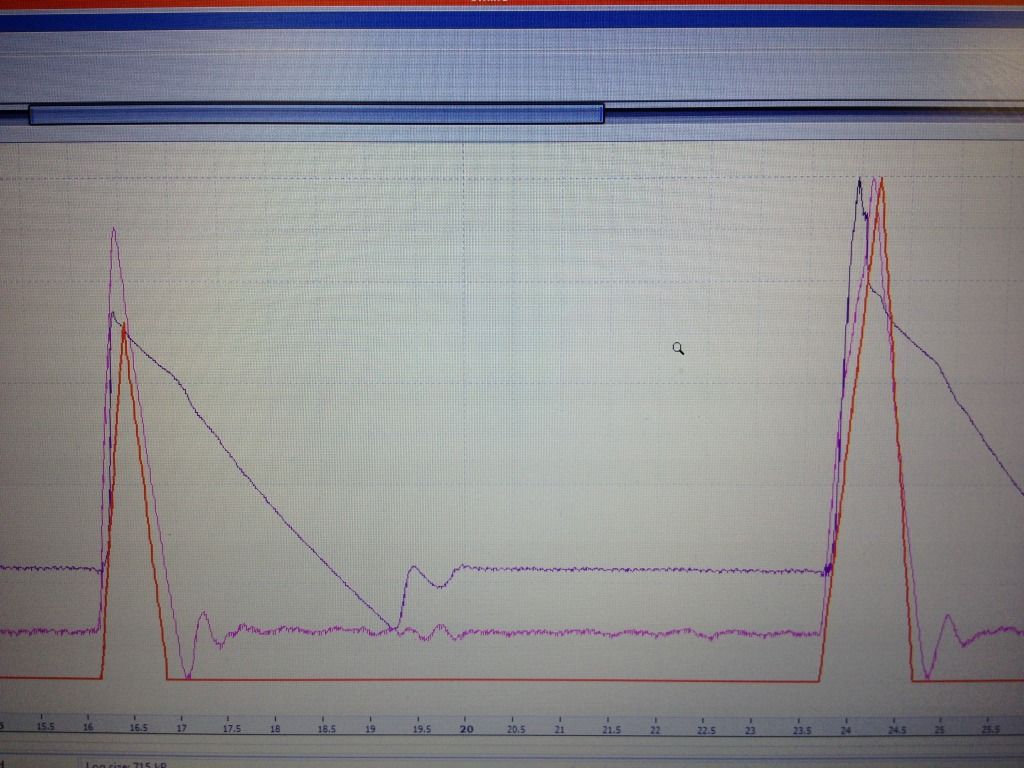

I'm only counting 2, or maybe I haven't had enough coffee this morn

Well he has two big shiney things on the top right plus the stock location? I dont do this letric stuff well.

I'm only counting 2, or maybe I haven't had enough coffee this morn

might be a tensioner in the stock location???

Affirmative. Three pumps. One nut.

Lol I should tube frame it! Then I'd have a truck in the mean time!

Some one has a thing for triplets LOL