Bodacious

Comp Diesel Sponsor

- Joined

- Jul 8, 2013

- Messages

- 2,177

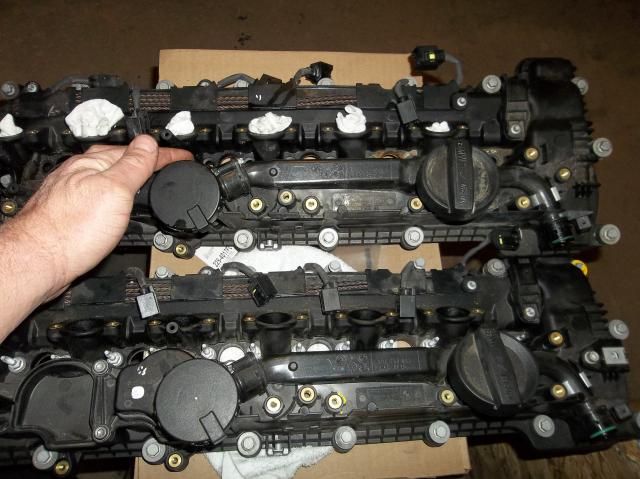

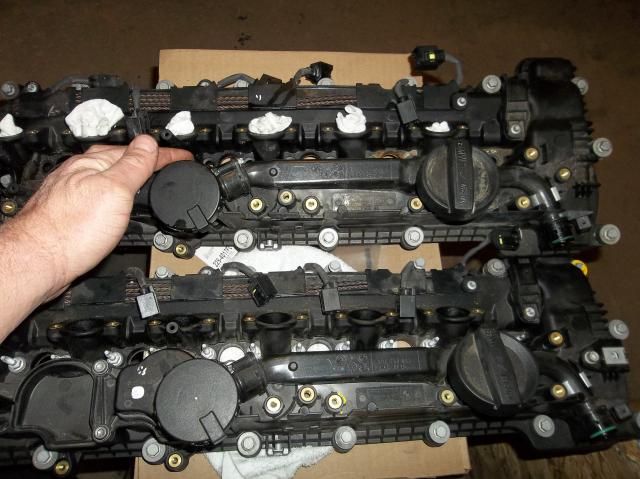

As some of you may remember, the valve cover on the BMW engine is composite and houses one set of intake ports. Right off the bat I realized this thing wouldn't hold in a high boost application.

Scott Law (chipmaker) built our current xfer case and wanted to take a look at the valve cover dilemma. This is the resulting cure so far.

Here are two of the factory valve covers. Lots of weirdness going on here.

Hoping the top of the engine will look much cooler once we get this thing fab'd up.

Scott Law (chipmaker) built our current xfer case and wanted to take a look at the valve cover dilemma. This is the resulting cure so far.

Here are two of the factory valve covers. Lots of weirdness going on here.

Hoping the top of the engine will look much cooler once we get this thing fab'd up.