You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

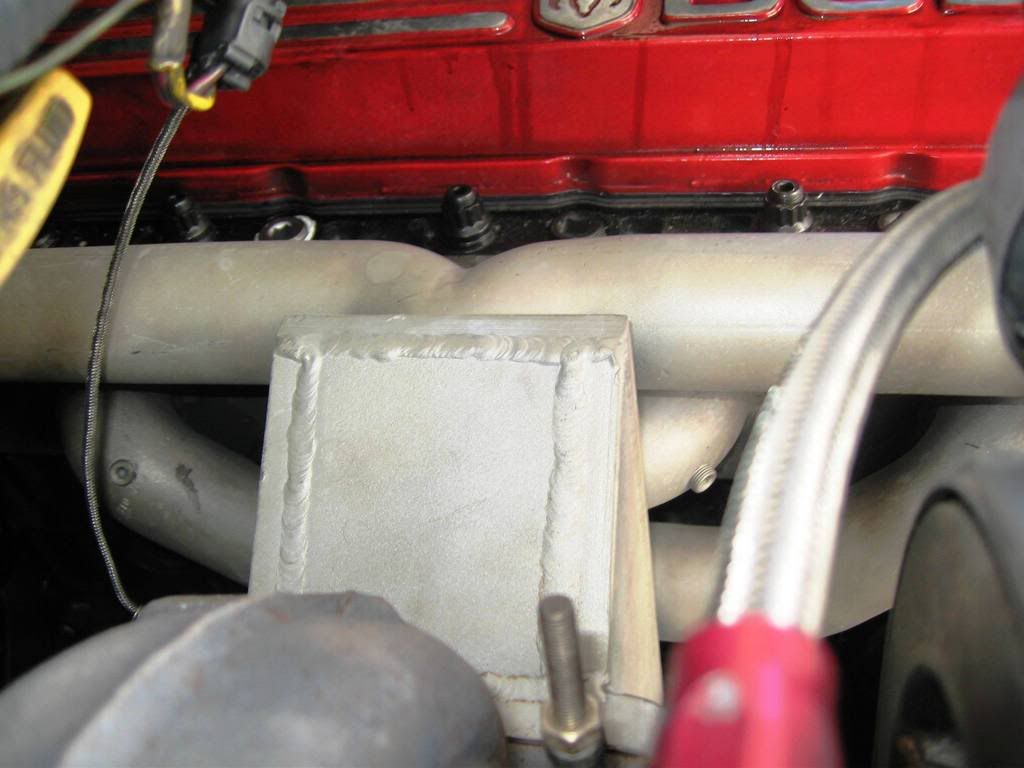

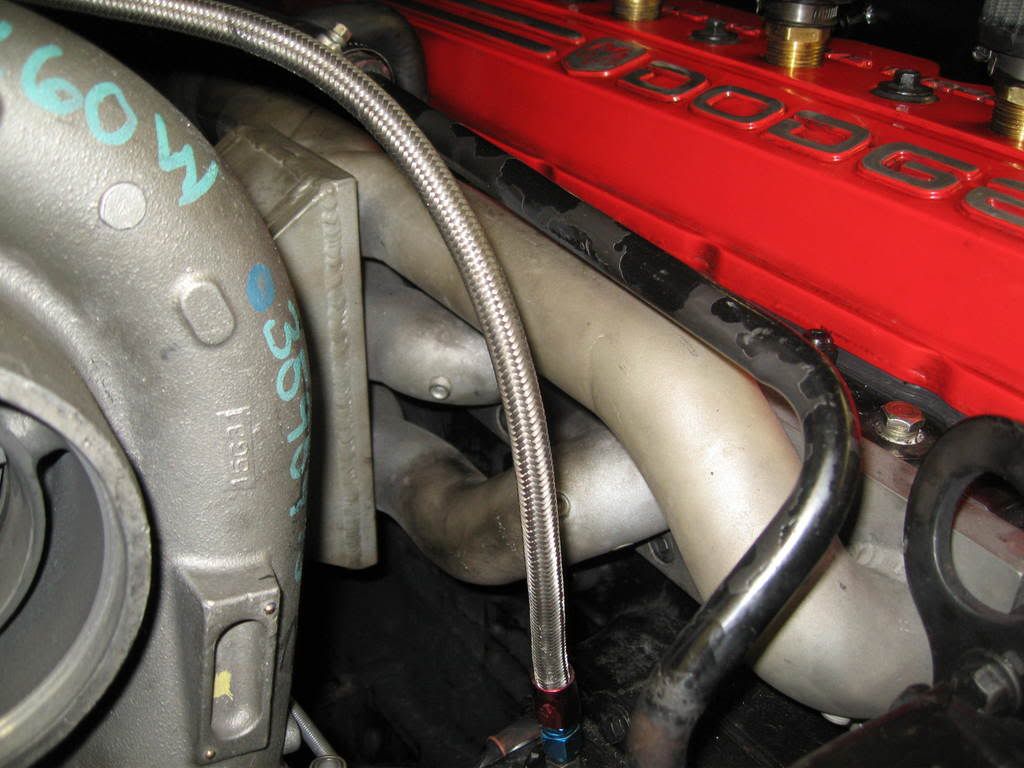

Someone had to do it, cummins tubular manifold.

- Thread starter PASSENGER

- Start date

Who has this one available and how much do they run?

I beleive comp461 sells them. I'm going to say 7-800? There was one in the classifieds for a 12v for $650.

I think it's one of the better designs out there with a true merge collector bringing the exhaust energy right to the turbine. The passenger one is the best design but it is way too large for most applications.

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

He was right. WHAT venturi. It is the type of chamber in the collector.

thanks. u are right. however i was just trying to be a wise guy in reference to the italian it was named after: giovanni

so what does the inside of the so called venturi look like to constrict flow??

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

Think about it like an hour glass, when air passes by the tight spot and then opens back up, the air speeds up! But don't think this would do any good in a turbo application on the intake side!!! Im thinkn it would just restrict the volume of air going in to the head...

COMP461

Comp Diesel Sponsor

- Joined

- Apr 23, 2006

- Messages

- 4,009

I have them, haw many do you want , Ive sold over 50 since this thread started .Who has this one available and how much do they run?

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

hmmmmmm what about these- they have em 6 into 1 ?

http://www.burnsstainless.com/MergeCollectors/TurboCollectors/turbocollectors.html

http://www.burnsstainless.com/MergeCollectors/TurboCollectors/turbocollectors.html

coon smile

New member

- Joined

- Oct 25, 2007

- Messages

- 3,399

I SEE :rockwoot:

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

Excluding packaging obstacle, performance opinion ?Engine bay space would be the largest obstacle.

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

Exactly. the transitional outlay of this set up is most optimal. I am currently considering this route. I am researching for the perfect component requirements with a custom header. I also have a connection with someone who has waterjet access for flanges.It's common practice in Turbo Performance, why not in a Diesel Application?

I think, with careful planning, it might fit and work. Obviously hookup to the down pipe will need to be altered- no big deal.

Also primary tube size selection has not been discussed.

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

Your opinion is noted, yet for conversational purposes-why not keep the primary size closer to the size of your exhaust port outlet, keeping the exhaust pulse consistant thru its pulse. This way there is full exhaust pulse velocity hitting what's after the T 4 flange. :ft:2" for a log-style with venturi, 1.25-1.5" for a tubular style header with merge collector. Of course these are just my opinions, my truck's blow smoke, I obviously don't know how to "turbocharge".

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

2" for a log-style with venturi, 1.25-1.5" for a tubular style header with merge collector. Of course these are just my opinions, my truck's blow smoke, I obviously don't know how to "turbocharge".

Your not far off at all! I used 2" pipe and had to put in a venturi.... So 1.5 may be right on... Those collectors are awsome!:rockwoot::bow:

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

Your opinion is noted, yet for conversational purposes-why not keep the primary size closer to the size of your exhaust port outlet, keeping the exhaust pulse consistant thru its pulse. This way there is full exhaust pulse velocity hitting what's after the T 4 flange. :ft:

Exhaust air speed has WAY more effect on spool up and driving the turbo then pulses...

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

My description above inquires about keeping the transition from exhaust port to turbo flange consistant. I want to take advantage of that pulse and plan to keep the series of pulses consistant. This would effectively capture improved spoolup in theory.Exhaust air speed has WAY more effect on spool up and driving the turbo then pulses...

I'm just a garage hack. $.02 I claim to know nothing.

UNBROKEN

Ezekiel 25:17

- Joined

- Apr 21, 2006

- Messages

- 17,158

Exhaust air speed has WAY more effect on spool up and driving the turbo then pulses...

I think you're forgetting about heat........

Burner

slow poke

- Joined

- Apr 24, 2006

- Messages

- 4,393

I obviously don't know how to "turbocharge".

Funniest thing I've heard all day.

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

I think you're forgetting about heat........

Don't know what ya mean... but hot air moves faster then cool air!

Last edited:

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

My description above inquires about keeping the transition from exhaust port to turbo flange consistant. I want to take advantage of that pulse and plan to keep the series of pulses consistant. This would effectively capture improved spoolup in theory.

I'm just a garage hack. $.02 I claim to know nothing.

IMO... theirs no "real" pulse in the header/manafold... theirs back PSI in their, so when air is being packed in the header the pulses become one. Just like an air compressor, the air is pumped in with a pulse(pistons pumping it in) but don't come out the hose pulsing... right???

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

Think about what you just wrote here..... your describing a manifold. the exhaust pulses dump into a runner where the rest of the exhaust pulses dump into where they then collect and dump into the T- flange. The header has a different design using cylinder outlet primaries which are individual and meet in a smooth transition that the merge collector provides,then the T- flange. Weston was pretty damned dead on with the call of 1.25-1.5 for the header and 2.0 for the log style manifold. You want it close to the size of the port outlet.:charger:IMO... theirs no "real" pulse in the header/manafold... theirs back PSI in their, so when air is being packed in the header the pulses become one. Just like an air compressor, the air is pumped in with a pulse(pistons pumping it in) but don't come out the hose pulsing... right???