You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

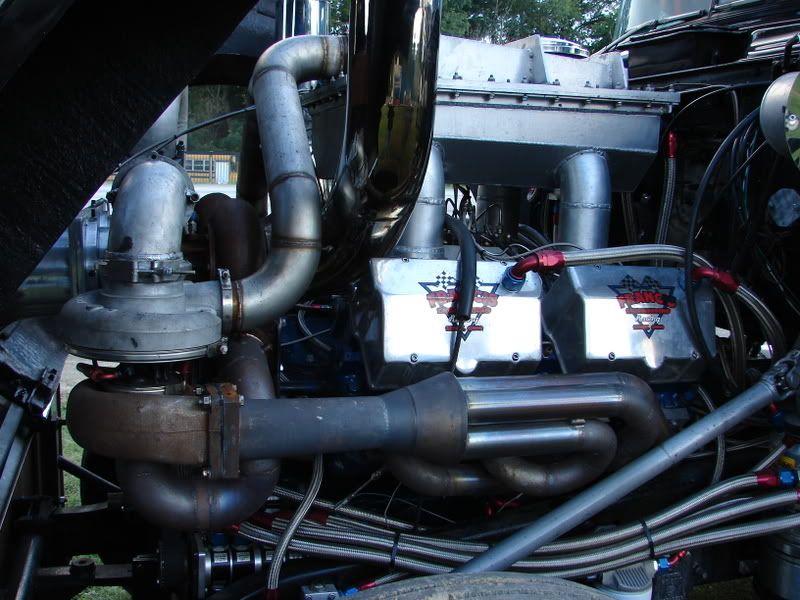

Someone had to do it, cummins tubular manifold.

- Thread starter PASSENGER

- Start date

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

Think about what you just wrote here..... your describing a manifold. the exhaust pulses dump into a runner where the rest of the exhaust pulses dump into where they then collect and dump into the T- flange. The header has a different design using cylinder outlet primaries which are individual and meet in a smooth transition that the merge collector provides,then the T- flange. Weston was pretty damned dead on with the call of 1.25-1.5 for the header and 2.0 for the log style manifold. You want it close to the size of the port outlet.:charger:

Weather it's a manifold or a header... your still going to have drive PSI/ back PSI in the header or the manifold!!!!!!!!!!!!!!!!!!!!! Put a pressure gauge on your header and see... I did! And the gauge don't pulse!

roachie

Taco Master

- Joined

- Nov 2, 2007

- Messages

- 11,133

Do you see the venturi collector on the manifold in the picture you posted here?

Yep, ignore me on that one. The way I read all that had me all mixed up.

TURBOLVR

Mr. Whipple

- Joined

- Mar 23, 2008

- Messages

- 2,566

Doesn't configuring the turbo like that add a bunch of thrust load to the CHRA bushings?

it will also cause oil to leak into the ex housing and have a tendency to starve the comp side bearings.:bang

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

I have a back pressure gauge which was in a stock manifold that beat itself to death from the pulses. Are you saying a full log manifold doesn't pulse at all?Weather it's a manifold or a header... your still going to have drive PSI/ back PSI in the header or the manifold!!!!!!!!!!!!!!!!!!!!! Put a pressure gauge on your header and see... I did! And the gauge don't pulse!

Hurley

BLAKLUNG

- Joined

- Apr 27, 2008

- Messages

- 3,698

you guys should check out "Scientific Design of Exhaust & Intake Systems," it can be had from Amazon.com for $20.

I think it has already been mentioned that all manifolds/headers will pulse, but those designed to maintain and even possibly magnify those pulse waves are going to improve performance. Although log manifolds do pulse, their design fails to convey those pressure waves optimally - and also the optimum flow velocity

I think it has already been mentioned that all manifolds/headers will pulse, but those designed to maintain and even possibly magnify those pulse waves are going to improve performance. Although log manifolds do pulse, their design fails to convey those pressure waves optimally - and also the optimum flow velocity

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

OMG....:doh:

XLR8R

Crew Chief

- Joined

- Sep 10, 2007

- Messages

- 2,364

you guys should check out "Scientific Design of Exhaust & Intake Systems," it can be had from Amazon.com for $20.

It's a good read - I've had my copy for 3 decades - but there are recent books that contain more relevant info.

Weather it's a manifold or a header... your still going to have drive PSI/ back PSI in the header or the manifold!!!!!!!!!!!!!!!!!!!!! Put a pressure gauge on your header and see... I did! And the gauge don't pulse!

Turbine Inlet Pressure & pulse waves certainly aren't mutually exclusive... standard gauges typically don't have the resolution to display individual pressure waves.

Also, Brandon, improperly designed TIP gauges can vibrate excessively from the CTD's harmonics and fail prematurely.

RacinDuallie

Black Sheep Racing

- Joined

- Apr 24, 2006

- Messages

- 17,383

You have a bank of 6 cylinders; what happens each time an exhaust valve closes ??? :bangOMG....:doh:

Hurley

BLAKLUNG

- Joined

- Apr 27, 2008

- Messages

- 3,698

It's a good read - I've had my copy for 3 decades - but there are recent books that contain more relevant info.

Could you shed some light on those books? I've not been able to find anything else with my searching....and boy do I feel young

brushpuller

Thinkin...

- Joined

- Nov 30, 2008

- Messages

- 630

Look, im not arguing with your guys about this, im just tryn to help out. Iv already done months of testing and already been down this road. Just tryn to save some of ya some time! This is the last post im puting on here... pulses DO NOT effect the driving of the turbo NEAR as much as exhaust air speed!

Last edited:

XLR8R

Crew Chief

- Joined

- Sep 10, 2007

- Messages

- 2,364

They're rather closely related - pulse frequency, duration & velocity are by necessity directly proportional to exhaust gas speed.

Pulse retention is a primary design factor for divided plenum manifolds and divided volute turbine housings.

We even fabricate divided T3 flanges for that very reason.

Pulse retention is a primary design factor for divided plenum manifolds and divided volute turbine housings.

We even fabricate divided T3 flanges for that very reason.

XLR8R

Crew Chief

- Joined

- Sep 10, 2007

- Messages

- 2,364

Could you shed some light on those books? I've not been able to find anything else with my searching....and boy do I feel young

Sir Henry Ricardo is a good place to start, and once you've digested Smith & Morrison you should read Hugh MacInnes (not quite as dated)... Mark Warner isn't too bad - fewer typos & mathematical errors than Corky Bell (which I don't recommend), and of course the relatively recent A. Graham Bell books are very helpful.

Those Aussies & Kiwis really know their stuff when it comes to high performance! :bow:

joefarmer

MR. Supreme Overlord

- Joined

- Jul 31, 2006

- Messages

- 6,137

Also, Brandon, improperly designed TIP gauges can vibrate excessively from the CTD's harmonics and fail prematurely.

Well, it was a 150psi air pressure gauge from an air compressor. :hehe: I definitely recommend steel wool or some sort of filter before the gauge. I believe it was the soot that finally killed it. Any other tips for TIP gauges?

tater_thrower76

New member

- Joined

- Apr 12, 2008

- Messages

- 856

Well, it was a 150psi air pressure gauge from an air compressor. :hehe: I definitely recommend steel wool or some sort of filter before the gauge. I believe it was the soot that finally killed it. Any other tips for TIP gauges?

in steam lines they have a circle bent up and put water in it so the steam doesn't eat away the gauge i would do the same w/ this only oil?

A tuned header isn't all ways equal length. The books mentioned are informative but I wouldn't hold them as gospel. They will explain alot of the therories behind header desing. I've seen alot of book desinged headers fall flat on their face on the dyno and the track. I know of a few popular pro stock teams that we've helped that have piles of headers in the corner that don't work. I wished it was as easy as reading a book. Throw a low rpm high torque engine that relies heavily on boost to shove air throughit into the equation and it's a differant ball game. As stated earlier in this thread equal length isn't quite a criticall on a turboed engine. I thinks it is still something to pay attention to. To toatally discredit it is foolish. The few things I've figured out is the diameter likes to be about 1.5" for up to about 600hp. 1.625" for above about 600hp. Length either way likes about 11" primaries and 6" secondairies. I also like to collect the front three together and the back three together 6-8" before the turbo. I've seen some improvement spooling by doing this. I belive it gets all the waves trucking straight before the turbo.Allowing the turbo to collect your header I belive creates turbulance and a restiction.

Scooter's Roofing

New member

- Joined

- Oct 16, 2006

- Messages

- 17,007

A tuned header isn't all ways equal length. The books mentioned are informative but I wouldn't hold them as gospel. They will explain alot of the therories behind header desing. I've seen alot of book desinged headers fall flat on their face on the dyno and the track. I know of a few popular pro stock teams that we've helped that have piles of headers in the corner that don't work. I wished it was as easy as reading a book. Throw a low rpm high torque engine that relies heavily on boost to shove air throughit into the equation and it's a differant ball game. As stated earlier in this thread equal length isn't quite a criticall on a turboed engine. I thinks it is still something to pay attention to. To toatally discredit it is foolish. The few things I've figured out is the diameter likes to be about 1.5" for up to about 600hp. 1.625" for above about 600hp. Length either way likes about 11" primaries and 6" secondairies. I also like to collect the front three together and the back three together 6-8" before the turbo. I've seen some improvement spooling by doing this. I belive it gets all the waves trucking straight before the turbo.Allowing the turbo to collect your header I belive creates turbulance and a restiction.

good post!!!