You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swole...Again!

- Thread starter jordanjames81

- Start date

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Hopefully all you need is a hone job. The rings should torque against the cylinder wall, even if it was the wrong way. You had to be pumping some major fuel and air to get all that oil to burn with it. I guess when you were not hotrodding it is when the top of the pistons filled and probably had a rough time buring during compression stroke and that is where the crappy running came in and left residue that carboned up?

I did my share of reg. driving and my share of hot rodding!

This sounds like it is what happened.

My pics tell a good story!!

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

You been wearing out the vw for six months, huh?

Dang skippy I have!! lol

jesnic

New member

- Joined

- Mar 16, 2009

- Messages

- 330

Well, hopefully Jeff will call me on Monday and tell me "come on down, you chit is ready". If not, maybe Tuesday. I need to get it to the body shop and have the dent repaired ad new windshield installed before I can give her heck again. Let me know if I can help. I ain't the smartest one out there but I do have two hands! I also know when all your parts fit loosely in a box or two, you got a problem.

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

I see lots of oil up where it should be limited. The top of the piston! Looks like you will get it sorted. Make dang sure the piston to wall clearance is where Mahle wants it.

Well at this point after we hone the block, im unsure what the PTW will be. It was just a tad larger then perfect last time. But I will have no choice but to run it just a tad large. It should run fine once broken in.

All out power is not the goal any longer.. Just keeping it running is!

Besides, with it being just slightly larger than perfect should keep the cylinder pressure down a bit and reliability up. Right??

Signature600

THA MAN!

- Joined

- Aug 5, 2006

- Messages

- 11,995

Well at this point after we hone the block, im unsure what the PTW will be. It was just a tad larger then perfect last time. But I will have no choice but to run it just a tad large. It should run fine once broken in.

All out power is not the goal any longer.. Just keeping it running is!

Besides, with it being just slightly larger than perfect should keep the cylinder pressure down a bit and reliability up. Right??

Tool large and you'll have blowby again.....

Chris

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Tool large and you'll have blowby again.....

Chris

Yeah, if its Too large for what Mahle says is ok then I guess I'll be backing up to punt!

I'm done dropping money in this thing.

But I'd like to say, had my oil scraper rings marked right and installed correctly that it would have run great. Hoping this will be the case for me this time.

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

Freezingsyztems you have A PM!

Just heard from Mahle. Turns out that Shauns ( the guy that told me his were marked wrong) rings were NOT marked wrong. There's always more to the story. That was My Bad for Posting before I knew... I appolize to Mahle!!

More to come later on my issue... Mahle will have them tmrw. I should have just waited I guess. Soon as they do the inspection and see, they told me I could share any info found, wether it was good or bad..

Just heard from Mahle. Turns out that Shauns ( the guy that told me his were marked wrong) rings were NOT marked wrong. There's always more to the story. That was My Bad for Posting before I knew... I appolize to Mahle!!

More to come later on my issue... Mahle will have them tmrw. I should have just waited I guess. Soon as they do the inspection and see, they told me I could share any info found, wether it was good or bad..

ktmracer21

smart a$$

- Joined

- May 11, 2009

- Messages

- 2,087

Freezingsyztems you have A PM!

Just heard from Mahle. Turns out that Shauns ( the guy that told me his were marked wrong) rings were NOT marked wrong. There's always more to the story. That was My Bad for Posting before I knew... I appolize to Mahle!!

More to come later on my issue... Mahle will have them tmrw. I should have just waited I guess. Soon as they do the inspection and see, they told me I could share any info found, wether it was good or bad..

watch what you here from him david. just another "me too me too" hell he cant even buy his own beer yet.:doh:

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

watch what you here from him david. just another "me too me too" hell he cant even buy his own beer yet.:doh:

LOL

Learning that now..

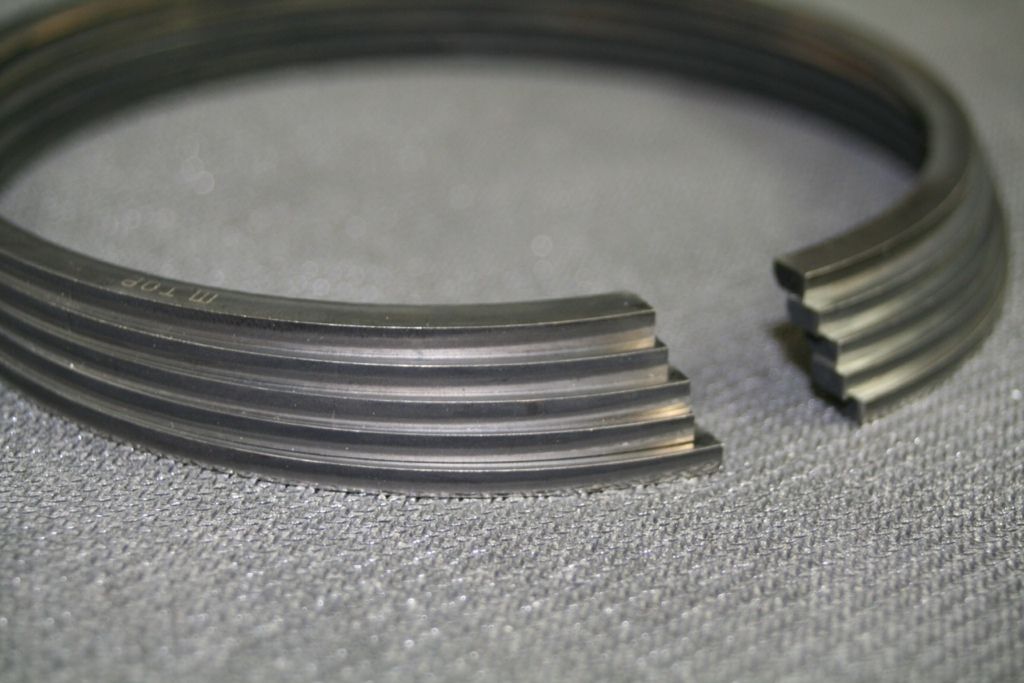

Btw , Here are Shauns actual rings that were sent back to Mahle for inspection. He only sent 5, as he kept one to use for cleaning the pistons I guess.

As you can see the marks for "top" vs the contact patch being on the bottom / opposite from the mark shows they were marked Correctly!

Shaun must have had a different issue as he did mention that he had way too much PTW clearance and complained about the machine shops work.

WUnderwood

Moderator

- Joined

- Aug 10, 2006

- Messages

- 8,418

David- could you sell the Monotherms and go back to a regular piston? seems like you have a lot of problems with them

ktmracer21

smart a$$

- Joined

- May 11, 2009

- Messages

- 2,087

from what i understand he took it to the machine shop in the back of a napa auto parts. these morons cant even spell cummins. we have shops that do tons of marine cummins motors...(on the 3 rivers here) shops that have been around longer than you lol. he cheaped out and it bit him. sledpuller21 was going to build the motor originally for 1400 i think. (his 2.6 truck never hiccuped all year, go figure)

around pittsburgh diesel is super small...ppl still think a smarty and flipped out mirrors are tough. we all tried to help him, but he knew more than us. i hold no grudge..simply try and use my experience to help

around pittsburgh diesel is super small...ppl still think a smarty and flipped out mirrors are tough. we all tried to help him, but he knew more than us. i hold no grudge..simply try and use my experience to help

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

David- could you sell the Monotherms and go back to a regular piston? seems like you have a lot of problems with them

from what i understand he took it to the machine shop in the back of a napa auto parts. these morons cant even spell cummins. we have shops that do tons of marine cummins motors...(on the 3 rivers here) shops that have been around longer than you lol. he cheaped out and it bit him. sledpuller21 was going to build the motor originally for 1400 i think. (his 2.6 truck never hiccuped all year, go figure)

around pittsburgh diesel is super small...ppl still think a smarty and flipped out mirrors are tough. we all tried to help him, but he knew more than us. i hold no grudge..simply try and use my experience to help

Once again, My appoligy to Mahle for posting info that I did not know for Sure was accurate!!

As for the monotherms.. I'll be keeping them. If my issue was only due to the 2nd ring being upside down, then there's No reason to say the pistons are causing the trouble.

Chris (joesixpack) has had great luck with them (old ones). He is currently modded and going to run some like mine. He just Modded his so that the oiling hole was in the stock location and would get the crown galley and wrist pin. Mahle is changing mine to this as Well. This was evidently NOT my issue as I had first suspected... All my rings had proper tension still on them, so an over heating issue was NOT the case.

Once they are modded and with the rings in the "proper" placement, I think they'll be the Cats A$$!!! I still Really like the idea of them Not being so heat sensitive as the stock pistons..

Who knows, Mahle may come back as say, "David, you're the dumba$$ that installed them incorrectly and that they were marked like they should have been" LOL

I may be the true idiot here!! I may be eating some Crow in the next few days.

Well see in the next two or three days though!

One thing IS for sure though.. Folks / and Companies can't say that I haven't helped them "Test and Develope" their Stuff!! LOL

I believe there will be a few that benefit from all this. "Freezingsystems" is going to benefit from having posted in here.. Mahle saw that his plates were missing and shouldn't be. So at least something good and further development for Better future products come from stuff like this... Agreed?

Last edited:

Freezingsystems

Modify Everything

- Joined

- Jan 18, 2010

- Messages

- 1,130

Once again, My appoligy to Mahle for posting info that I did not know for Sure was accurate!!

As for the monotherms.. I'll be keeping them. If my issue was only due to the 2nd ring being upside down, then there's No reason to say the pistons are causing the trouble.

Chris (joesixpack) has had great luck with them (old ones). He is currently modded and going to run some like mine. He just Modded his so that the oiling hole was in the stock location and would get the crown galley and wrist pin. Mahle is changing mine to this as Well. This was evidently NOT my issue as I had first suspected... All my rings had proper tension still on them, so an over heating issue was NOT the case.

Once they are modded and with the rings in the "proper" placement, I think they'll be the Cats A$$!!! I still Really like the idea of them Not being so heat sensitive as the stock pistons..

Who knows, Mahle may come back as say, "David, you're the dumba$$ that installed them incorrectly and that they were marked like they should have been" LOL

I may be the true idiot here!! I may be eating some Crow in the next few days.

Well see in the next two or three days though!

One thing IS for sure though.. Folks / and Companies can't say that I haven't helped them "Test and Develope" their Stuff!! LOL

I believe there will be a few that benefit from all this. "Freezingsystems" is going to benefit from having posted in here.. Mahle saw that his plates were missing and shouldn't be. So at least something good and further development for Better future products come from stuff like this... Agreed?

This thread indeed has saved me some future trouble and I thank you Again Swole for your great informative threads. Just got off the phone with Eric @ Mahle great people as always they are hooking me up also thanks to you Swole. :clap:

Thanks again, Chris

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

There were two different ring sets from Mahle.

One part # has superseaded the old.

These drawings of the scraper ring was sent to me for comparison by Mahle... The Chamfer is oppisite on one set from the other.

How is the chamfer on a stock Cummins set?

Sorry for the pic quality.. I could not get photobucket to upload them the way Mahle sent them, so I had to result to taking a pic of the screen with my phone.

As you can see, the wear marks should be toward the bottom of my pistons where as my wear marks were on top.. As the piston was coming down the wall, I guess it was trapping oil in the upside down gap and causing it to lift and let oil pass by to the top rings.

One part # has superseaded the old.

These drawings of the scraper ring was sent to me for comparison by Mahle... The Chamfer is oppisite on one set from the other.

How is the chamfer on a stock Cummins set?

Sorry for the pic quality.. I could not get photobucket to upload them the way Mahle sent them, so I had to result to taking a pic of the screen with my phone.

As you can see, the wear marks should be toward the bottom of my pistons where as my wear marks were on top.. As the piston was coming down the wall, I guess it was trapping oil in the upside down gap and causing it to lift and let oil pass by to the top rings.

Last edited:

Big Swole

MegaInterceptor

- Joined

- Jun 28, 2007

- Messages

- 16,950

This thread indeed has saved me some future trouble and I thank you Again Swole for your great informative threads. Just got off the phone with Eric @ Mahle great people as always they are hooking me up also thanks to you Swole. :clap:

Thanks again, Chris

Thanks Chris!

Very glad to hear that something good came from this!

Just hope Eric's not too upset with me..:lolly:

Can't wait to get my truck running now

Dockboy

Comps BFF

- Joined

- Apr 26, 2006

- Messages

- 3,341

That was My Bad for Posting before I knew...

Still haven't learned your lesson huh?