You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

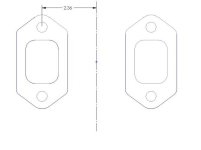

Tubular Exhaust Manifold

- Thread starter SPEEDSHIFT

- Start date

SCHOOL BUS

DLRA T-O

- Joined

- Jun 27, 2007

- Messages

- 10,513

bodie...does ashley know how to weld? looks like you got lots of headers to fab up! oh and i got my ap90's in the mail this week!!!!

SPEEDSHIFT

New member

- Joined

- Jan 30, 2007

- Messages

- 5,978

LOL Naaaahh she cant weld. I say "baby all you have to do is stand there and look good, ill do the rest":hehe: We are both content.:hehe:

Let me know how those injectors work out for ya, Ryan is wanting some real bad as well.:rockwoot:

Let me know how those injectors work out for ya, Ryan is wanting some real bad as well.:rockwoot:

SPEEDSHIFT

New member

- Joined

- Jan 30, 2007

- Messages

- 5,978

Bodie, do you have any stickers made up? I wouldn't mind throwing one on my truck.

Bryce, Ill get you one man. I think I have some left from Baytown.

ride42

980MW

- Joined

- Jan 1, 2007

- Messages

- 4,506

Bryce, Ill get you one man. I think I have some left from Baytown.

Thanks very much.:rockwoot:

getblown5.9

Ceritified Kleenex Dealer

- Joined

- Aug 3, 2006

- Messages

- 7,259

i gotta start getting into some more CAD stuff so some day i can make some custom parts for the truck!

SPEEDSHIFT

New member

- Joined

- Jan 30, 2007

- Messages

- 5,978

i gotta start getting into some more CAD stuff so some day i can make some custom parts for the truck!

Man that CAD stuff is sweet, I was looking into Solid Works a couple years ago, you can do stress analisys, heat, friction, all kinds of cool stuff.:rockwoot:

ward.racing

black smoke addict

- Joined

- Mar 11, 2008

- Messages

- 268

if you ever need another tester or even when you get it done. Im game. Running twins and still seeing around 1500-1600 degrees.

Diesel Freak

Active member

- Joined

- Jun 20, 2007

- Messages

- 1,164

Solidworks is the shiznit!!!

Autocad blows goats!!

Autocad blows goats!!

SPEEDSHIFT

New member

- Joined

- Jan 30, 2007

- Messages

- 5,978

I will start the betas soon, and I will keep you guys updated with pics. There will be some T4 and T3 headers for 12v and 24v for you guys to see. Also a better finished 3rd gen T3 with wj flanges.:rockwoot:

diesel junkie02

I NEED MORE COWBELL!!

- Joined

- Feb 19, 2007

- Messages

- 134

there is a company called Houston Unlimited Inc. in chappel hill,tx. and they do metal coatings and its a dul black or shiney black (whichever you choose) coating that makes it rust proof and can take the high temps of exhaust manifolds.

the coatings are used to harden surfaces and make the metal more "slippery" (less friction) when oil is gets on it with out distorting tight tolerences for the guys who want to free up some hp they could help by coating cranks,ring & pinion, etc. they process parts for MSD and AJ Foyt

the prices are calc. by weight not sure what the price is but its under a dollar per pound.

the coatings are used to harden surfaces and make the metal more "slippery" (less friction) when oil is gets on it with out distorting tight tolerences for the guys who want to free up some hp they could help by coating cranks,ring & pinion, etc. they process parts for MSD and AJ Foyt

the prices are calc. by weight not sure what the price is but its under a dollar per pound.

wpeschel

Psyko

- Joined

- Aug 4, 2007

- Messages

- 872

there is a company called Houston Unlimited Inc. in chappel hill,tx. and they do metal coatings and its a dul black or shiney black (whichever you choose) coating that makes it rust proof and can take the high temps of exhaust manifolds.

the coatings are used to harden surfaces and make the metal more "slippery" (less friction) when oil is gets on it with out distorting tight tolerences for the guys who want to free up some hp they could help by coating cranks,ring & pinion, etc. they process parts for MSD and AJ Foyt

the prices are calc. by weight not sure what the price is but its under a dollar per pound.

Do they have a website??? I wonder how well these coatings would hold the heat in the header??? HMMMM Wesley

pullinpower

New member

- Joined

- Jul 29, 2007

- Messages

- 64

there is a company called Houston Unlimited Inc. in chappel hill,tx. and they do metal coatings and its a dul black or shiney black (whichever you choose) coating that makes it rust proof and can take the high temps of exhaust manifolds.

the coatings are used to harden surfaces and make the metal more "slippery" (less friction) when oil is gets on it with out distorting tight tolerences for the guys who want to free up some hp they could help by coating cranks,ring & pinion, etc. they process parts for MSD and AJ Foyt

the prices are calc. by weight not sure what the price is but its under a dollar per pound.

I really like this Idea... the salt bath part of process is sort of how high end custom rifles are blued.

The only thing wrong with that is to get the cost down on the flanges I have to buy at least 4 of each type, along with drawing fees it is close to $2000 for the investment. I just dont have that kind of money right now.

That's insane!

Sorry, I realize I am a new poster here, but they are hosing you.

PM me and I will draw it for free, put it in .DXF format to do a direct burn, and get quotes from the Laser guys next door. ( central Illinois )

If you can rough sketch it out, I can draw it and email it in .PDF for you to print and hold over the manifold to verify before they burn.

kxhonda

New member

- Joined

- Feb 8, 2007

- Messages

- 393

Like I seaid earlier a laser would be much cheaper than water jet. Laser will give you plenty good enough cut quality.

That's insane!

Sorry, I realize I am a new poster here, but they are hosing you.

PM me and I will draw it for free, put it in .DXF format to do a direct burn, and get quotes from the Laser guys next door. ( central Illinois )

If you can rough sketch it out, I can draw it and email it in .PDF for you to print and hold over the manifold to verify before they burn.