1badcummins4321

Diesel Guru

- Joined

- Feb 5, 2011

- Messages

- 81

Naw, no need to bump up the idle, just turn it into a lope.

Agreed

Naw, no need to bump up the idle, just turn it into a lope.

Joe,

I've done some quick searching and I believe the PD (BEW) TDI's are single injection event and run at 26,000psi (or something along them lines) all the time. The BEW is significantly quieter then the ALH (PD vs VP injection).

What I'm getting at is, multiple events are not necessary what makes stuff quieter.

Joe,

I've done some quick searching and I believe the PD (BEW) TDI's are single injection event and run at 26,000psi (or something along them lines) all the time. The BEW is significantly quieter then the ALH (PD vs VP injection).

What I'm getting at is, multiple events are not necessary what makes stuff quieter.

You are right about VW tdi I have 2009 2.0 and 2001 tdi

iPhone: In for the ride; http:s985.photobucket.com/home/dzzlpwr/index

I'll admit I have just about ZERO experience with the TDI's.....just going from what I read a while back was the BEW's are using a plunger/cylinder along with a solenoid that gives complete control over timing......so they could be retarding the timing somewhat to control noise.

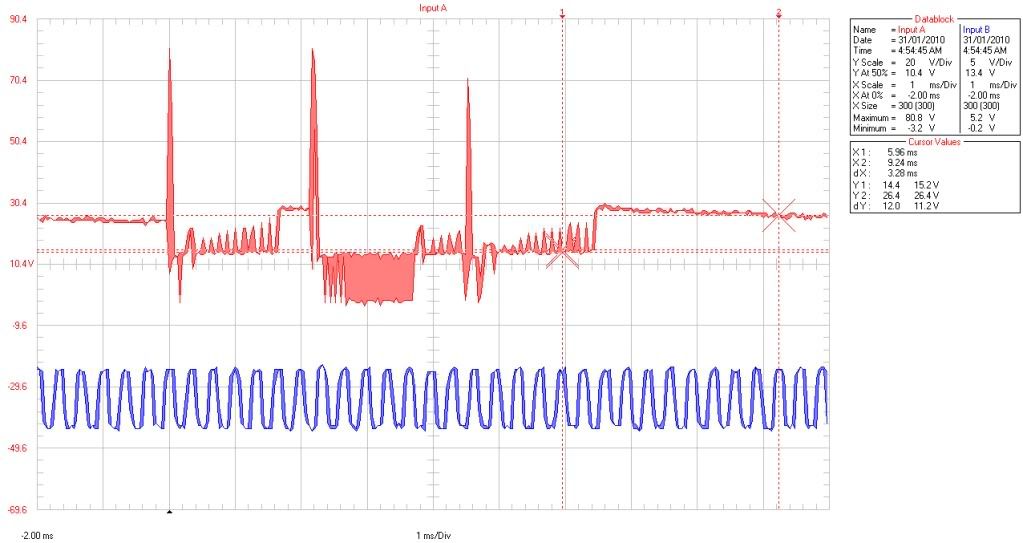

Which brings me to what I've found was to quiet a single event down, without changing the initial start of injection or (timing), you can lower rail pressure to where you are spreading the single event out through more crank degrees.

More or less "filling the window". This quiets it considerably and in effect you are retarding the timing. (Lower pressure more duration).

BUT....at a cost of some atomization....(remember huge nozzles)...this is were the split main comes in.....Use two shots at higher pressure that are spaced out. Now you still have good atomization, very quiet combustion that is spread out.

At high rpm though, it really comes down to time, at that point I'm just down to one event, in an effort to get as much fuel in the injection window.

Also.... would like to see the rest of the post tables.

Do you have a video or could you make one to see how quiet the pilot with split main is?

I'll show you mine if you show me yours...LOL

Post injection timing table, just one of them. This is how many degrees after TDC the post is injected.