You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Perkins rebuild and Allison6sp swap

- Thread starter 2wpuller

- Start date

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

working on making the fanshroud for the electric fan.I just got delivery of the electric motor for my mill I guese lightning got it.after I get the shroud done going to make a Y fitting for my return lines for PS and Hydroboost.

Dale

Dale

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

I got the fan shroud done saturday.I had to use the bed of the truck to bend the sheetmetel kind of crude but it worked.My wife had to give me a helping hand holding the parts in place while I clamped things together to bend them.She gave me permision to buy a brake from Harborfreight.I'm useing the electronic relay from the ford car to turn the fan on I need to pick up a temp sensor for a 05 ford car.

JakeDiesel

New member

- Joined

- Jan 8, 2009

- Messages

- 415

nice work

What is that fan out of. I seen the temp sensor is out of and 05 and the relay out of the car. Did i read over it?

What is that fan out of. I seen the temp sensor is out of and 05 and the relay out of the car. Did i read over it?

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

My soninlaw works at a body shop and got it off a wrecked full size ford 05 the shroud was broke so they put a new one in.This thing puts out alot of air.I have to get the wiring diagram for that car to find out what sensor to use.I will get all the part no. for the reley and sensor.

O by the way this is the original radiator that came with the truck when my dad got it new in 1975 for $6500.00 it has never been repaired.I know I just jinks it.

Dale

O by the way this is the original radiator that came with the truck when my dad got it new in 1975 for $6500.00 it has never been repaired.I know I just jinks it.

Dale

Last edited:

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

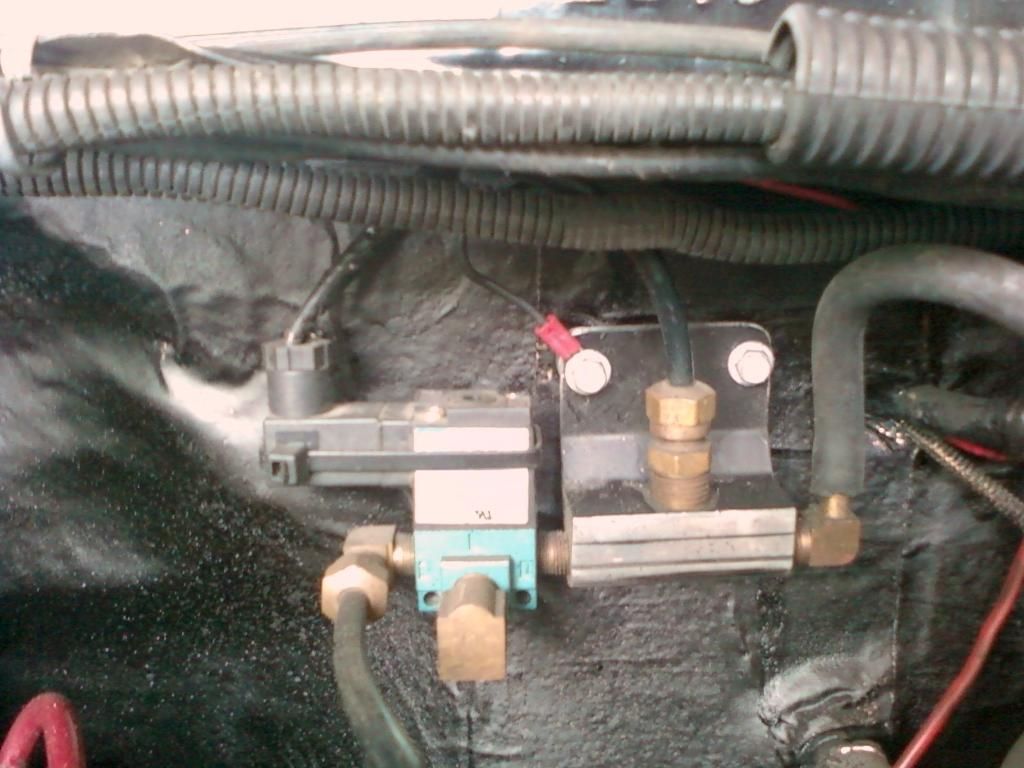

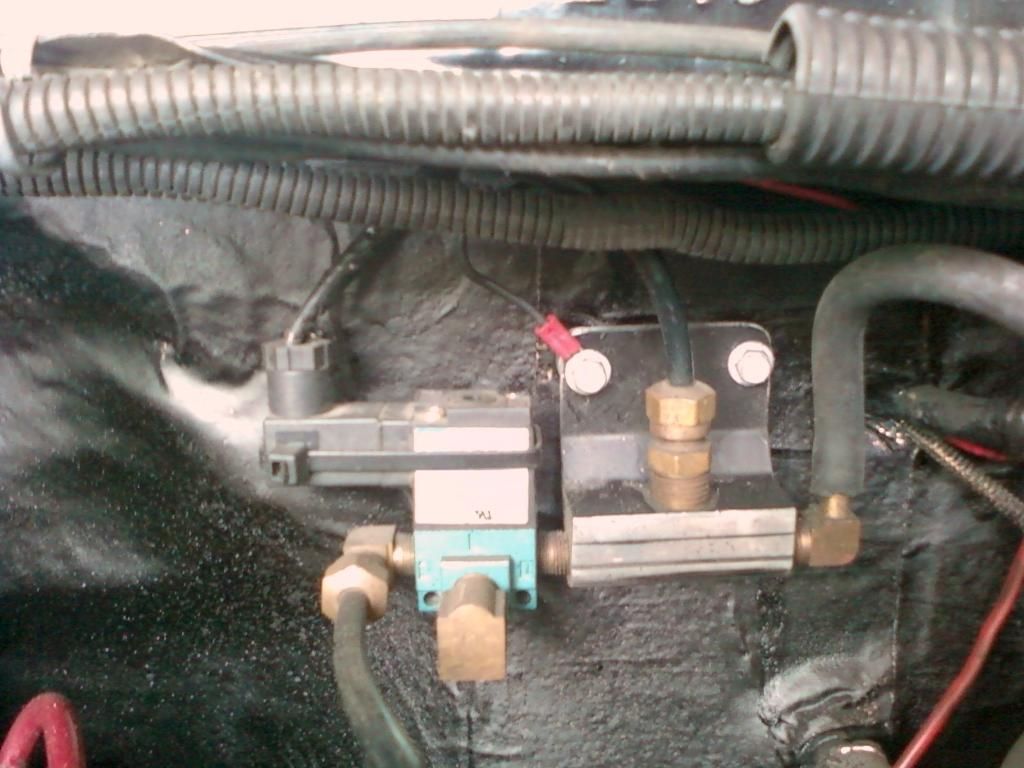

AC condensor mounted waiting for the dryer and compressor.

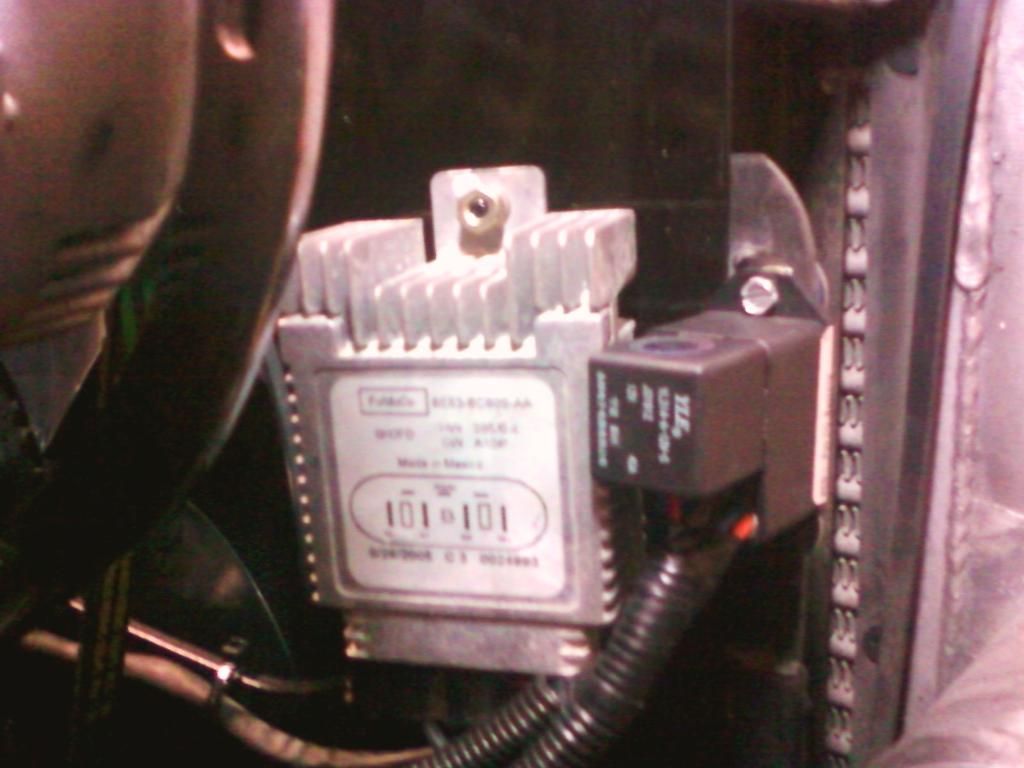

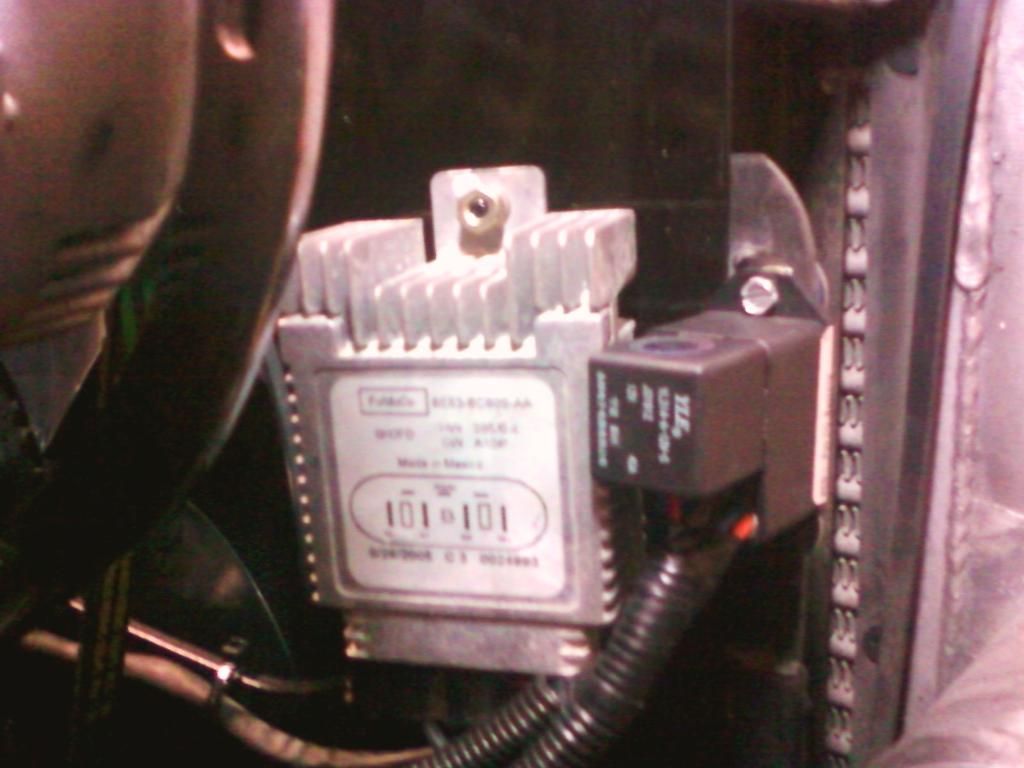

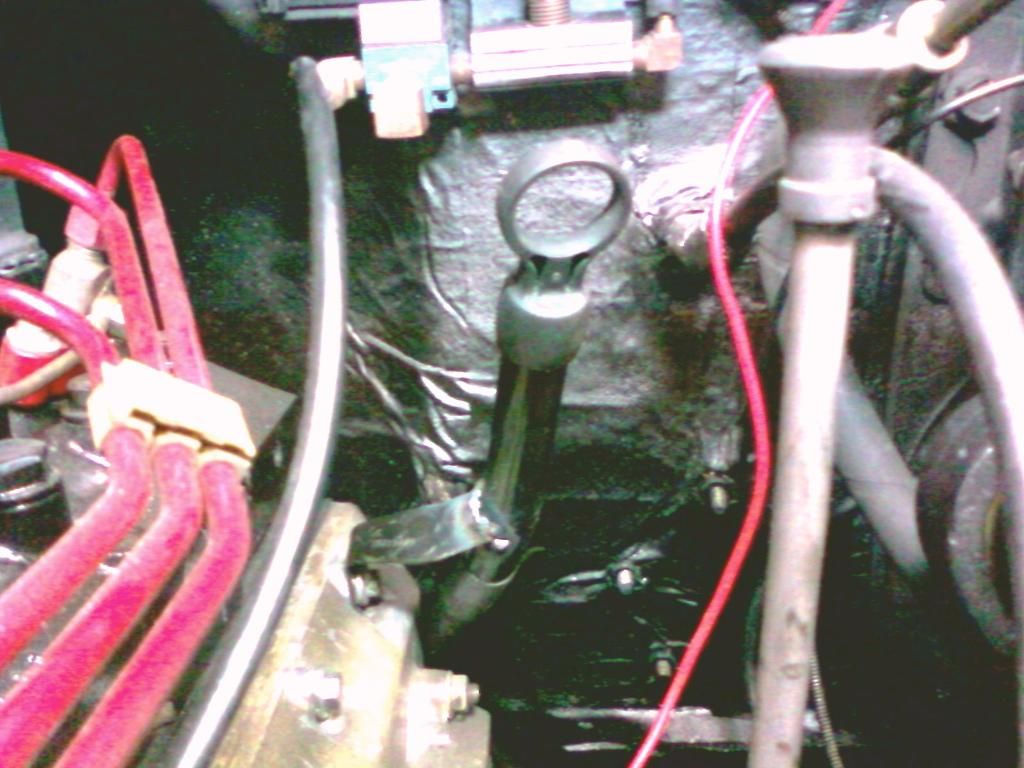

This is a closeup picture of the fan reley from the ford car.

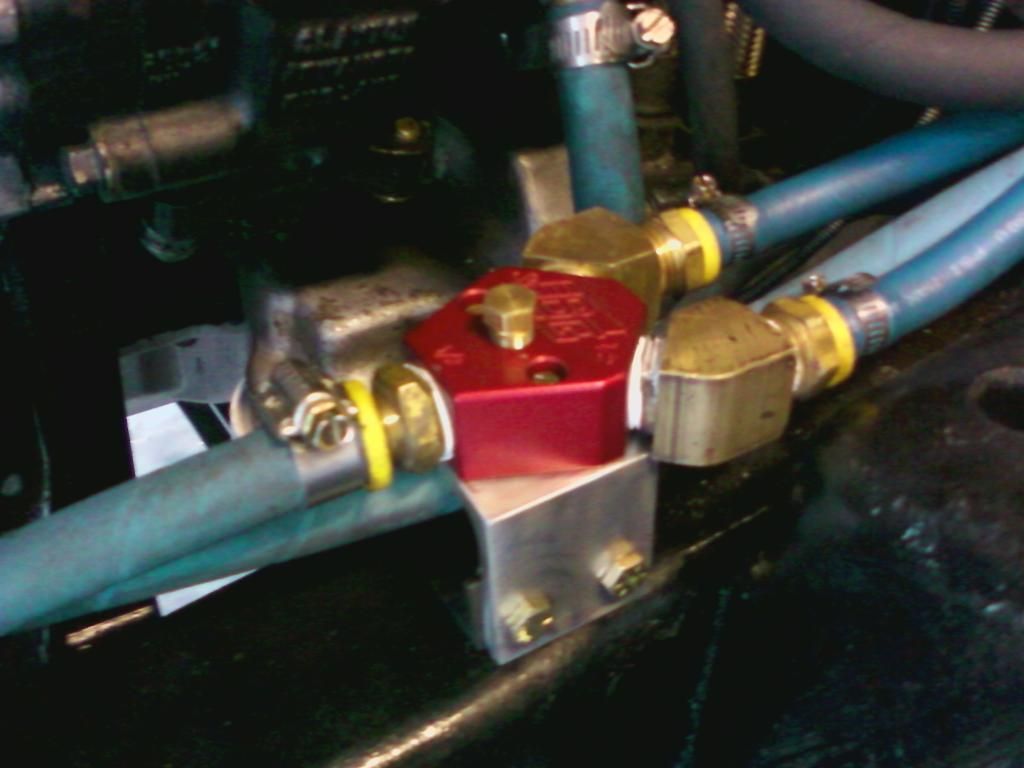

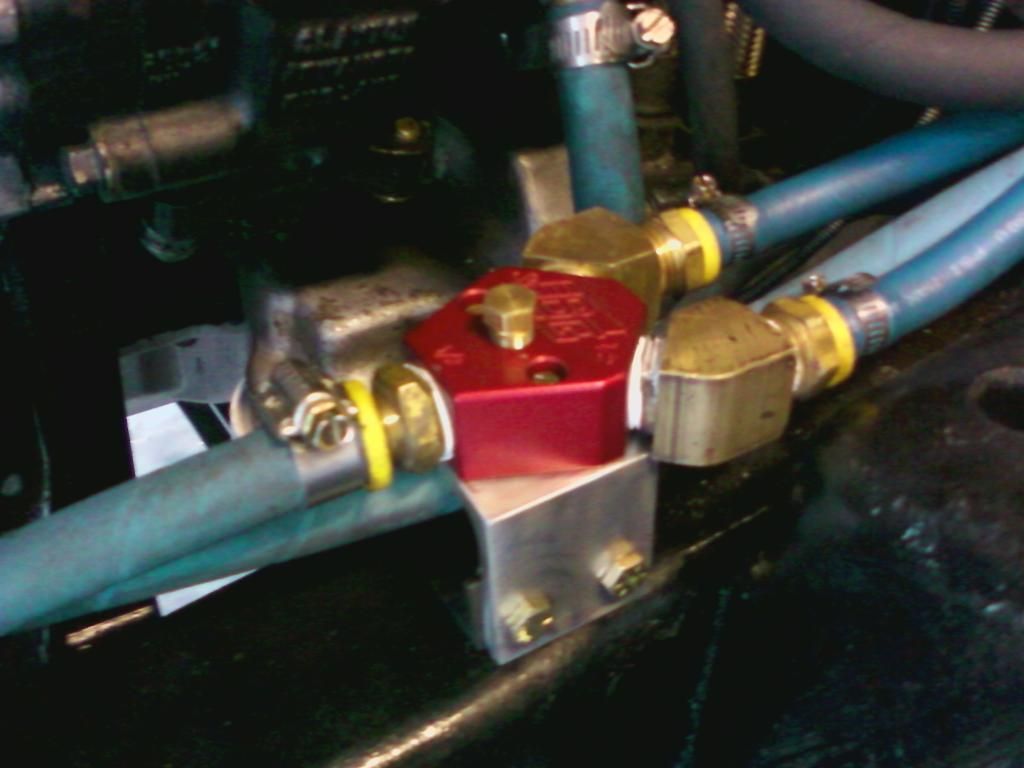

Picked up a power stearing resevor it was brush finnished I had to polish it after i made all the brakets and ran the hoses.Only had one return line so I picked up a fuel block to run the 2 3/8 into a 1/2 then went to the cooler then to the resevor.

I polished the air gov for good messure

Dale

This is a closeup picture of the fan reley from the ford car.

Picked up a power stearing resevor it was brush finnished I had to polish it after i made all the brakets and ran the hoses.Only had one return line so I picked up a fuel block to run the 2 3/8 into a 1/2 then went to the cooler then to the resevor.

I polished the air gov for good messure

Dale

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

I went to the parts store to get a temp,sending unit for the 2005 ford car that the fan came from it was almost 60.00 the parts book didn't have the temp, listed for the sensor.

i ended up getting a Hayden universal unit it is adjustable from 215 to 165deg.I used it inconjucktion with the ford reley.

The valve for the valiegh switch

I made the dipstick tube out of the original one from the 06chevy I cut off the bottom "3 after it came out of the trany and cut the tube off of the top 6" and used 5/8 air line and slid the air line into the original tipstick tube then used heat shrink to seal them together.

i used part if the original bracket that held the tube to the bellhousing on the chevy did some beating with a hammer and welded it in place.

The 06 chevy stearing columb peice that coverd shifter will work for a mold for my stock Ford columb with some modifications.

I might use the key hole for the exhaust brake switch.

Think I going to mount the TCM and BCM on a plate under my center consol above my radio amp,

Or does enyone think the amp.mite cause a problem with the TCM and BCM.

Dale

i ended up getting a Hayden universal unit it is adjustable from 215 to 165deg.I used it inconjucktion with the ford reley.

The valve for the valiegh switch

I made the dipstick tube out of the original one from the 06chevy I cut off the bottom "3 after it came out of the trany and cut the tube off of the top 6" and used 5/8 air line and slid the air line into the original tipstick tube then used heat shrink to seal them together.

i used part if the original bracket that held the tube to the bellhousing on the chevy did some beating with a hammer and welded it in place.

The 06 chevy stearing columb peice that coverd shifter will work for a mold for my stock Ford columb with some modifications.

I might use the key hole for the exhaust brake switch.

Think I going to mount the TCM and BCM on a plate under my center consol above my radio amp,

Or does enyone think the amp.mite cause a problem with the TCM and BCM.

Dale

Dazed&Confused

Surfing my own world

- Joined

- Jun 27, 2006

- Messages

- 2,533

Im right there with you Dale i hate wiring.

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

The heatshrink that I used on the dipstick tube for the alison was some cheap stuff didn't have any glue inside it wouldn't hold the tubes together.

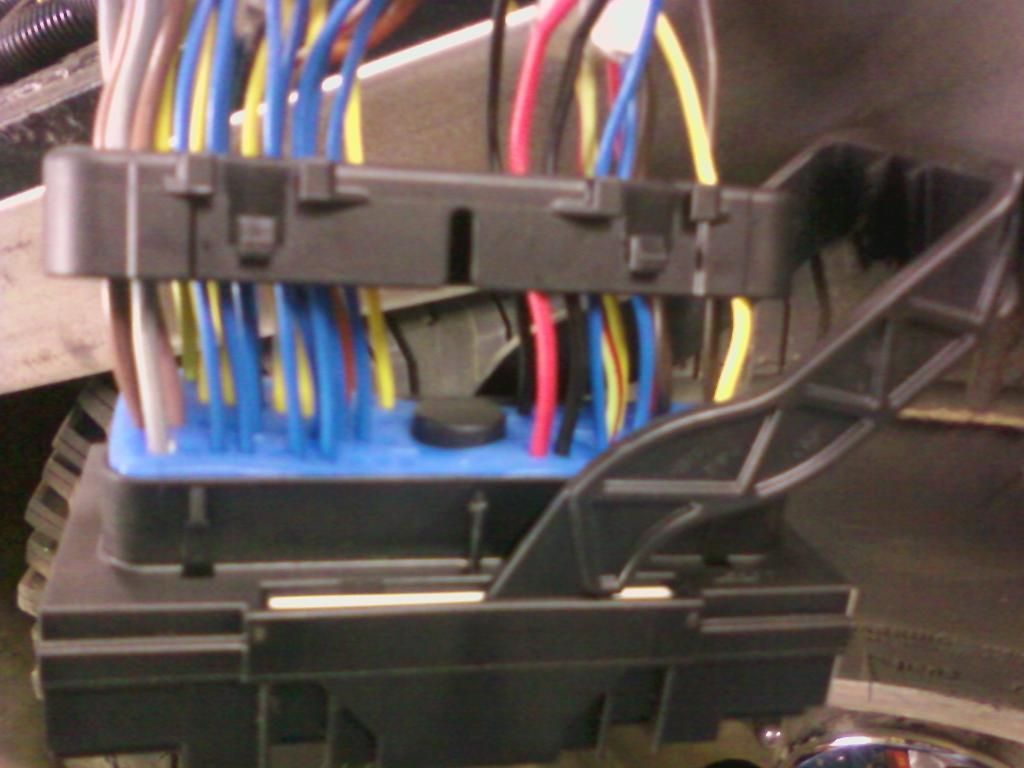

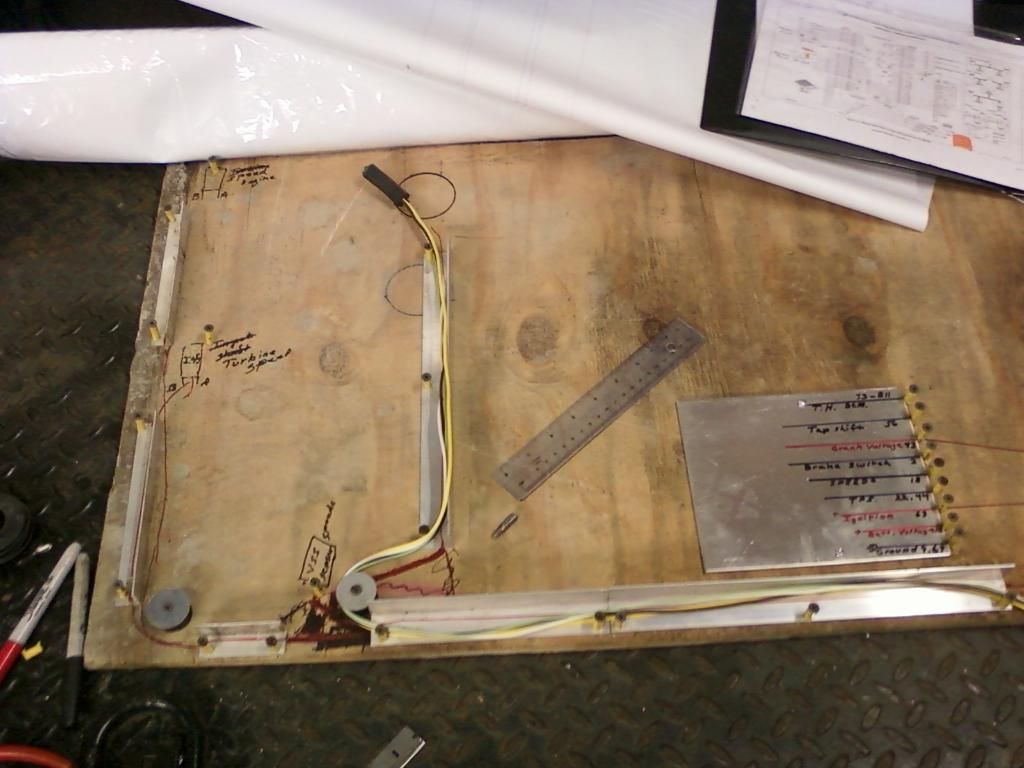

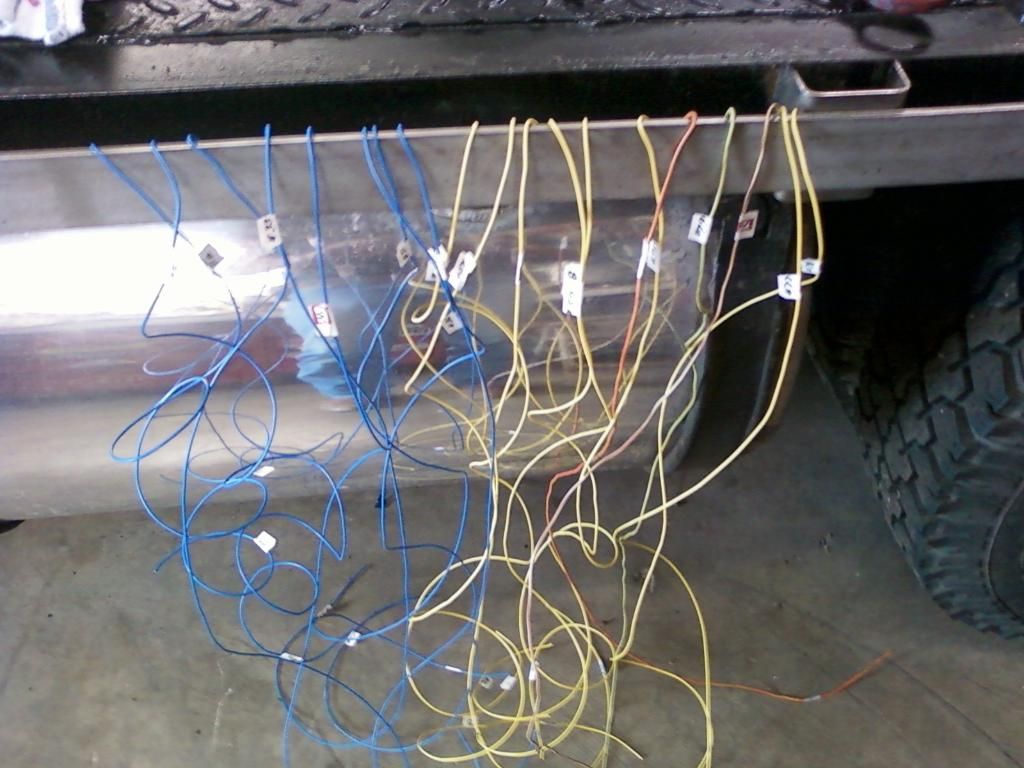

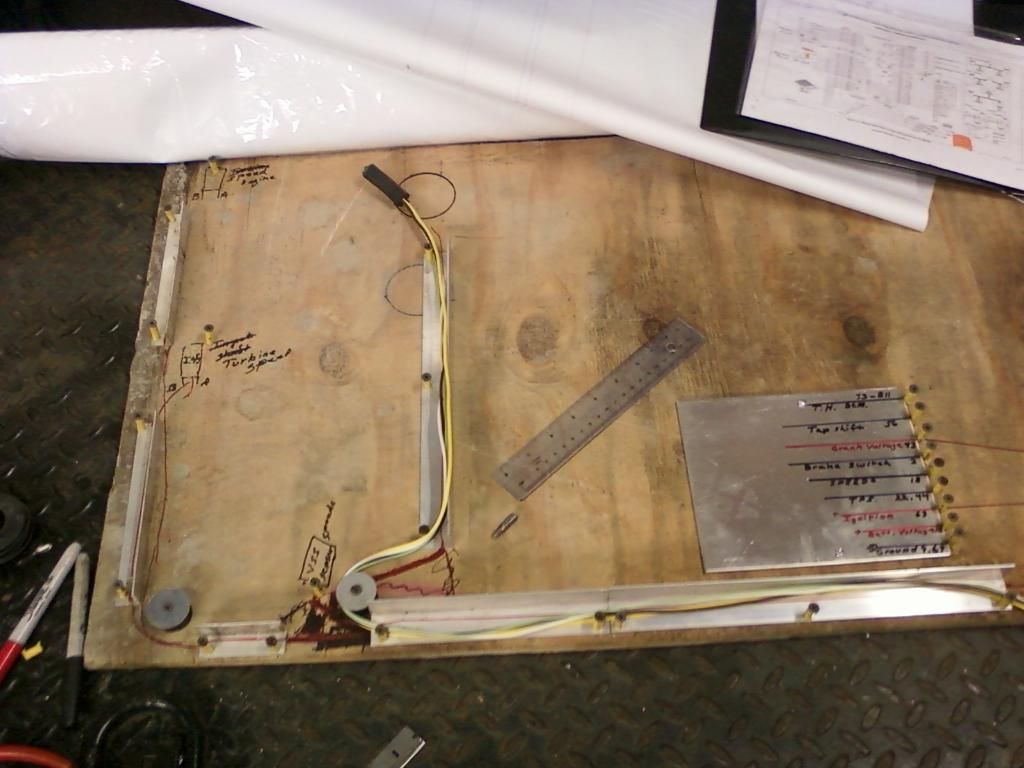

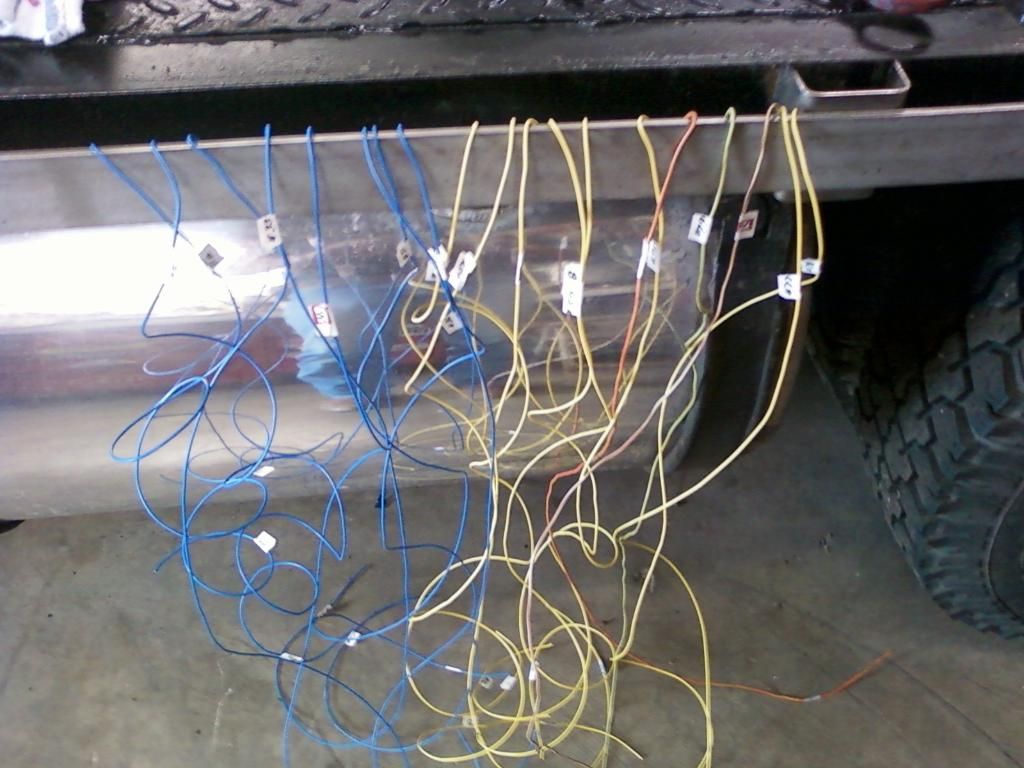

the board for the patern for the wiring harnes.

had to twist the wire for the sencors has to have 16+-4 raps per foot.

now all I have to do is put the plug end on and install it and program the trany with EFI.

Another good reason to have a flatbed make one heck of a work bench and catchall.

Dale

the board for the patern for the wiring harnes.

had to twist the wire for the sencors has to have 16+-4 raps per foot.

now all I have to do is put the plug end on and install it and program the trany with EFI.

Another good reason to have a flatbed make one heck of a work bench and catchall.

Dale

2wpuller

letting the smoke fly

- Joined

- Dec 27, 2006

- Messages

- 2,894

Thanks guys.I finally got all but one plug for the BCM.We hooked the EFI up to the TCM lastnight and it was able to read and flash it just fine. will post some more pictures later.going to install the harness today and connect the wires from the columb.

Dale

Dale

Dazed&Confused

Surfing my own world

- Joined

- Jun 27, 2006

- Messages

- 2,533

You do awesome work Dale.