WUnderwood

Moderator

- Joined

- Aug 10, 2006

- Messages

- 8,418

lets keep it civil folks, or take it to PM's

Anyways........ i know i have asked this many times already and really hate to burn it out but... Yall mean out of all of the homemade ported/polished heads out there in this country that only one or two of yall have taken pics...???

come on now

Lance

Don't you know Lance everything is a BIG secret , ........oooooooohhhhhh........aaaaaaahhhhhhhhh..........and smoke and mirrors..... in the diesel world. ....

:hehe::hehe::hehe:

You don't need to cut like a mad man, you'll see were it needs it. Get your self a set of good carbides, I like the "flame" tip I call it, pretty universal, the exaust side will be HARD from heat treatment.

On a all out race head you might cut right into the guides, but IMO its not worth it.

Can't find my photo's of the intake cut off and the porting on that side.....:bang

I agree this is a great site with a lot of good guys on it. I was only directing my comment at very few individuals but they know who they are.

Back on track: I like the carbide bits that are more round and remember slower is better on carbide bits. Get some coarse cartridge rolls and you should be good to go.

Joe : those are very nice, hope you don't mind me copying I based my head off your pics. :rockwoot:

MLR, thanks for the pics and the ideas. How did you build the head stands? What turbine inlet flange you using on the exhaust manifold?

How are you planning on getting the intake manifold to seal-up with 100psi of boost? I thought about using orings around the ports.

Keep the pics coming for us to drool on buddy.:bang

also remember if you get the long madrels with large rolls to go VERY SLOW! I found out later that theyr'e not rated for high speed. You will actually bend them over in a 90 degree. I would of took pics but was too embarrassed and doubled over in pain when it took out my knee and jeans. :bang:doh:

Some pics of my intake, CR in a Ford chassis. Back ones are on angle for firewall clearance.

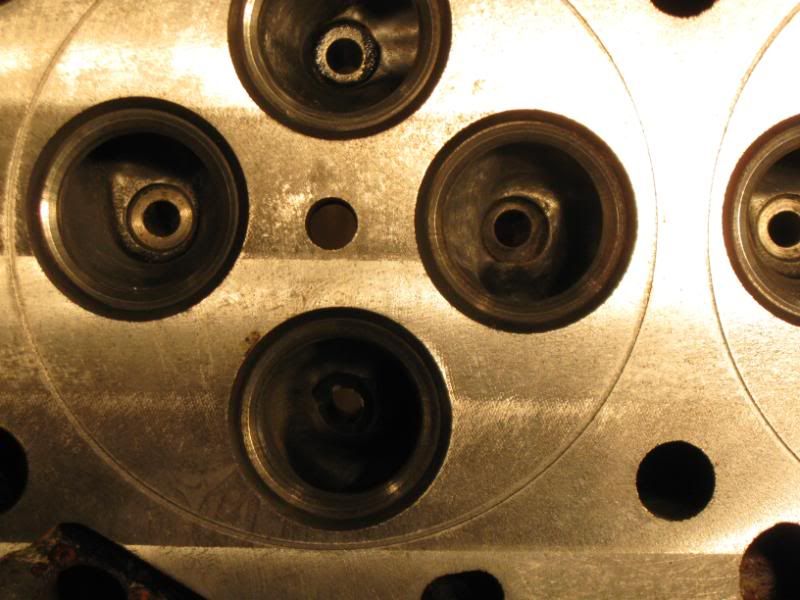

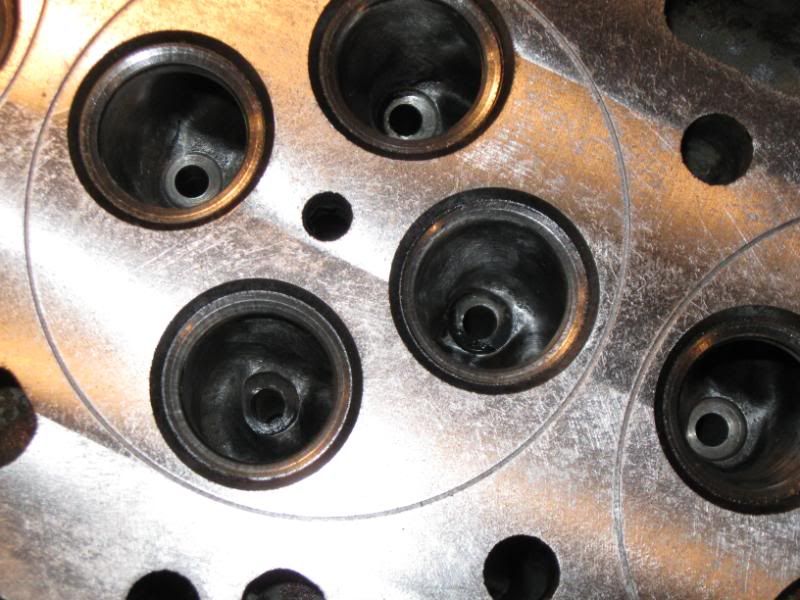

There's some pictures of a 24 valve head job, you will have a rough idea of what is wrong with the #1 and #6 runners

View attachment 16124